The decision between lead-acid and lithium-ion forklift batteries is one of the most important choices warehouse operators face. Each option offers distinct advantages depending on your application, operational demands, and budget.

In this comprehensive guide, we’ll break down the key differences in maintenance, charging, energy efficiency, and cost to help you make an informed decision.

What are Lead-Acid Forklift Batteries?

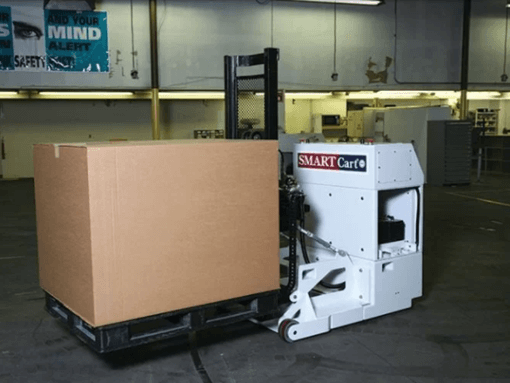

Lead-acid forklift batteries have been the industry standard for decades. These rechargeable batteries are known for their affordability and reliability. Often called motive power batteries, they not only power forklifts but also act as a counterbalance, preventing tipping when lifting heavy loads.

While a car battery typically weighs around 40 lbs, lead-acid forklift batteries can weigh anywhere from 800 to 4,000 lbs. This weight serves a dual purpose: powering the forklift and stabilizing it when handling loads of up to 36,000 lbs.

What are Lithium-Ion Forklift Batteries?

Lithium-ion batteries represent the next generation of power solutions for forklifts. Made with lightweight materials and advanced technology, these batteries offer high energy density, long life cycles, and minimal maintenance requirements.

Though lighter than lead-acid batteries (weighing 500–2,500 lbs), lithium-ion models sometimes require additional counterweights to ensure forklift stability. Their quick charging capabilities and consistent performance make them increasingly popular in modern warehouses.

Lead-Acid vs. Lithium-Ion: Key Differences

Maintenance Requirements

Lead-Acid Batteries

Lead-acid batteries require frequent maintenance to stay operational. This includes:

- Watering: Water is needed to maintain electrolyte levels. Overwatering or underwatering can damage the battery.

- Servicing: Batteries must be cleaned regularly to control acid buildup and corrosion.

- Inspection: Vent caps and electrolyte levels must be checked to ensure safe operation.

Maintenance for lead-acid batteries is labor-intensive and often requires specialized training or assistance from material handling professionals.

Lithium-Ion Batteries

Lithium-ion batteries require almost no maintenance. They do not need watering, and routine checks are limited to inspecting plugs, cables, and chargers. Additionally, keeping the battery at room temperature and avoiding deep discharges ensures long-term performance.

Winner: Lithium-Ion

Charging Efficiency

Lead-Acid Batteries

Charging lead-acid batteries is a time-consuming process. A full charge takes about 8 hours, followed by an 8-hour cooling period. This means warehouses operating multiple shifts often need additional batteries to keep forklifts running continuously. Lead-acid batteries generally last around 1,500 charge cycles with proper care, equating to 3.5–5 years of use.

Lithium-Ion Batteries

Lithium-ion batteries offer significant advantages in charging efficiency. A full charge takes only 1–4 hours, and the batteries can be opportunity charged during breaks or between shifts. With a lifespan of 2,000–3,000 charge cycles, lithium-ion batteries outperform lead-acid in longevity and reduce downtime.

Winner: Lithium-Ion

| LEAD-ACID | LITHIUM-ION | |

|---|---|---|

| Use Time | 8 Hours | 8 Hours |

| Charge Time | 8 Hours | 1-4 Hours |

| Cool Time | 8 Hours | 0 Hours |

| Total Time Needed Before Use | 16 Hours | 1-4 Hours |

Energy Usage & Efficiency

Lead-Acid Batteries

Lead-acid batteries are less efficient due to their lower energy density (80–90 Wh/L). They also lose energy during charging and operation, meaning forklifts may experience reduced performance as battery levels drop. For example, a forklift that lifts 3,500 lbs at the start of a shift may only lift 2,600 lbs after several hours of operation.

Lithium-Ion Batteries

Lithium-ion batteries provide much higher energy density (100–265 Wh/kg) and maintain consistent voltage throughout their discharge cycle. This results in steady performance and up to 50% energy savings compared to lead-acid batteries. Additionally, lithium-ion batteries eliminate the need for dedicated charging spaces, freeing up valuable warehouse space.

Winner: Lithium-Ion

Upfront Cost

Lead-Acid Batteries

Lead-acid batteries are more affordable initially, with costs ranging from $5,000 to $12,000 depending on size and specifications. This makes them a practical choice for smaller operations with limited budgets.

Lithium-Ion Batteries

Lithium-ion batteries are more expensive upfront, costing between $17,000 and $25,000. However, their longer lifespan, lower maintenance costs, and energy efficiency provide a higher return on investment over time.

Winner: Lead-Acid

Which Forklift Battery is Right for Your Warehouse?

Choose Lithium-Ion Forklift Batteries If:

- You operate a multi-shift warehouse and need minimal downtime.

- Energy efficiency and long-term cost savings are priorities.

- You want to eliminate time-consuming maintenance tasks like watering.

Choose Lead-Acid Forklift Batteries If:

- Your operation is single-shift or intermittent.

- Budget constraints make a lower upfront cost essential.

- You can manage the additional maintenance and charging time.

Final Verdict: Lead-Acid vs. Lithium-Ion

Lithium-ion batteries are the clear winner for modern, high-demand operations. They deliver superior charging efficiency, minimal maintenance, and consistent energy performance, making them ideal for multi-shift warehouses.

Lead-acid batteries, on the other hand, remain a solid choice for smaller-scale operations with fewer forklifts and less frequent usage. Their lower upfront cost can be a practical advantage in scenarios where downtime and maintenance are less critical.

By evaluating your specific needs, you can select the forklift battery that maximizes productivity and reduces operational costs in your warehouse.

Common Questions about Forklift Batteries

When to Add Water to a Forklift Battery?

The best time to water your batteries is right before a shift, after the batteries have had time to cool down.

How Long do Forklift Batteries Last?

Lead-acid batteries will last 1,500 charging hours if maintained well. Lithium-ion batteries will last 2,000 to 3,000 charging hours.

Do Propane Forklifts Have Batteries?

Yes, propane forklifts have batteries. However, unlike electric forklifts the purpose of the battery on propane forklifts is not to produce power, it is to help start the forklift.

How Much Does a Forklift Battery Weigh?

A forklift battery weighs between 800 to 4,000 lbs. depending on the type (lithium-ion vs lead-acid) and size (24V, 36V, 48V).