What is One-Piece-Flow Manufacturing?

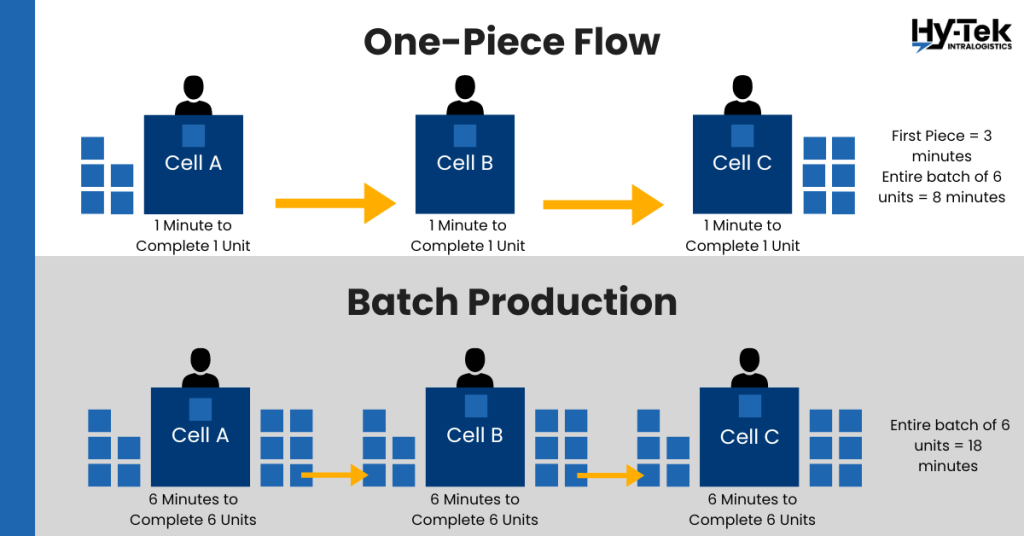

One-piece-flow manufacturing means that goods flow continuously through each step of the process one by one, meaning goods are not batched together before moving on to the next step in the process.

This technique, also called “single piece flow,” helps manufacturers work faster and be more efficient because they can focus on one thing at a time and make sure it’s done right before moving on to the next thing.

One-Piece Flow vs Batch Production

One-piece flow manufacturing and batch production are two different approaches in manufacturing. In a one-piece flow, items are made one at a time, moving from one step to the next as soon as they are completed. This method allows for better quality control, reduces inventory, and improves efficiency by focusing on individual items.

On the other hand, batch production involves making a large number of items at once before moving them to the next step. This approach can be more cost-effective for certain products and processes.

One-piece flow is ideal for high-quality, customized products with short lead times, while batch production is suitable for standardized products with economies of scale. The choice between the two depends on factors like product complexity, demand variability, and cost considerations.

Benefits of One-Piece Flow Manufacturing

One-Piece-Flow Manufacturing, like many other lean manufacturing concepts, can seem like just another flashy buzzword. However, utilizing this strategy can lead to tangible real-world improvements in your facility. So, what are the real advantages of implementing a one-piece-flow manufacturing process in your facility? Let’s take a look below.

Space Savings

Converting your facility to a one-piece-flow manufacturing operation can drastically reduce finished inventory levels as well as work-in-progress (WIP) levels. Because WIP proceeds almost instantaneously to the next work center in this format, there is no need for an extended queue between each process step.

Additionally, customer orders can be handled on more of a Just-In-Time basis which equates to quicker inventory turns and ultimately less finished inventory on hand. These reductions translate to a reduced need for sprawling facilities to accommodate massive inventory levels. Similarly, the lack of dependence on WIP can (and should) allow for more compact work centers or cells eliminating the need for space between each step in the production process.

In today’s climate where industrial real estate has never been in greater demand, those space savings can translate to hefty sums of money via leasing smaller facilities or through cost avoidance by eliminating the need to move your operation to support your business’s growth.

Labor Savings

The main way in which one-piece-flow manufacturing can reduce your labor spend is through reduced travel time. As mentioned above, work cells should be constructed where the production steps are located very close together. The need for travel time between stations is then greatly reduced, specifically in terms of transporting enormous amounts of WIP in between these process steps.

Additionally, due to the reduction in WIP and inventory noted above, labor will be saved through reduced inventory control efforts such as reduced cycle counting efforts, less frequent need for a P.I., and quicker loading times due to being able to stage the majority of the finished inventory near the point shipment.

Quality Improvement

One of the pitfalls of batch manufacturing is that without a robust quality control system at each machine center, the impact of quality nonconformances is amplified. Significant financial loss is realized through non-conforming WIP that must be scrapped, the labor to do so, and via the impact this has on achieving service levels every time a quality excursion occurs.

By implementing one-piece-flow manufacturing, quality issues are discovered much more quickly as WIP almost instantly gets consumed at the subsequent station. This allows for a real-time reaction to quality issues occurring at the prior station or issues with the raw materials themselves. This scales down the financial impact and lost production time substantially when quality issues do arise.

Service Level Increase

By moving from batch processing to a single-piece flow, production queues at workstations are drastically reduced. Ideally, no more than a dozen units of WIP exist in between each step of the manufacturing process. This makes the full production process more flexible and capable of adapting to customer demand. This flexibility is key in offering shorter lead times to customers on a wider variety of products, not to mention accommodating changes to customer orders.

Conclusion

Like any process change, converting your facility to a one-piece-flow manufacturing process will require a well-organized plan and time investment to ensure successful implementation. A helpful tip is to begin closely tracking machine uptime and quality control statistics, if this is not being done already. Because reliable quality control and consistent machine uptime are cornerstones of successfully converting to, and running, a one-piece-flow manufacturing process, it’s wise to start working towards achieving elevated quality levels and machine uptime. This will make the conversion process a much smoother transition. Once this has been established, the transition to a one-piece-flow manufacturing setup can be made in order to realize each of the benefits listed above, giving your facility and your operation an efficiency boost and a level of adaptability that allows your business to keep up with growing demand and other external challenges when they arise.