Expanded growth in the eCommerce business sector or planning for emergence from the COVID-19 pandemic may represent just a couple of reasons that a company may be moving towards a new Operations Design. This may be to improve the Operations of an existing facility or a move to or expansion into a new facility. Whatever the reason for your decision there are a few basics steps that need to be taken to ensure you achieve a better Operations Design.

The three basic steps to a better design include:

Step 1: Assess Your Current State – “Know Where You Are”

Step 2: Plot Your Course – “Know Where You Are Going”

Step 3: Data & Growth – “Understand Where You Want to Be”

Step 1: Assess Your Current State…This is typically a relatively easy task when you have an existing operation and are looking at growing organically or selling more of the same products. The more difficult scenario could be you are looking to add new brands to your portfolio, or you are moving from a retail-based operation to a multi-channel operation supporting both retail and online purchases. In any scenario following are some sample questions that will need to be addressed:

- Do I have documented SOPs for my current Operations? If the answer is “No” this may be one of the first tasks you undertake

- Do I have Keys Performance Indicators (KPIs) for each Functional Area in my Operation? These KPIs are critical for developing a business case for the project and ultimately measuring the success of the project as you compare the existing KPIs against the new ones

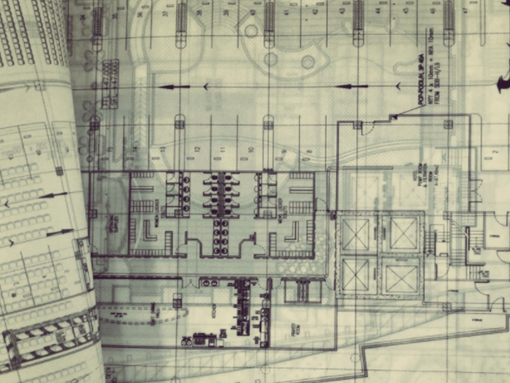

- What existing Facility and Material Handling Assets do we possess? Detailed drawings and an inventory of existing assets is a valuable starting point for a new operations design.

- Are there any existing Lease or Service agreements that will be changing in the near term? Or are you in long term agreements that cannot be altered?

Step 2: Plot Your Course…Know where your Operation is going. Are you looking to expand your operation to accommodate volume growth? Are you looking to automate to reduce your demand in a shrinking labor market? Is your company looking to meet higher service levels as demanded by your online customers? Are you looking to extend the life of your current facility or shrink into a smaller footprint? Maybe it is a combination of all of these or other goals that your business is driving you to. Whatever the reason, you need to chart the proper course with all the milestones to achieve along the way. You need to design with the end in mind.

To begin your effort, you will need to know your objectives:

- Improving service Levels, Next-day, or Same-day Deliveries

- Reduced transportation costs

- Reducing labor reliance

- Consolidated shipments

- “Store Friendly” or “Shelf Ready” shipments

- Reduced Back-room Sizes

- Omni-channel Distribution

- Automated Receipts

- Reduced Inventory, Better Inventory Control

- Bring more Value-Added Services to your products

You will also need to evaluate the impact on the Current Operation such as:

- New Warehouse Management System (WMS) or significant Modifications to the Existing one

- Building Modifications like expansion, more electrical power required, Flat/Level Floors, improved lighting, expanded fire-protection or added platforms or mezzanines

- Additional Training for the Associates and Managers

- Change Management

- Commitment of Critical Resources to the Project

Step 3: Data & Growth – Understand Where You Want to Be

Every Good Design is based on Design Parameters that are typically derived from historical data. Normally a full year’s worth of data gives the best result because it contains seasonal peaks. Once the data has been analyzed you can develop the design parameters using maximum values, average values, minimum values, and the standard deviation from the median numbers. With those you can derive the following:

- Your peak to average ratios or peaking factors

- Understand operational “Outliers” such as new product introductions, new store openings, mergers & acquisitions

- Classification of products by movement, typically “A” = fastest movers, “D” = Slowest movers, “E” = Seldom Movers

- Know when product movement classifications change during the lifecycle such as seasonal changes

- Be clear about U.O.M. or Unit of Measure. Is it a master case, a case, an inner pack, a unit, a pallet?

How will your Distribution Center (DC) Operation grow? What Processes need to change?

- Growth Type

- Organic Growth – Sell More of the Same

- Sales Channel Growth – Move to Multi-channel DC of Omni-Channel Network

- Product (SKU) Growth

- Merger & Acquisition

- All of the Above or Some composite of all of the above

- Growth Volume

- Balanced Annual Growth

- Growth in New Channels Only, maybe Retraction in Existing Channels

Using these three basic steps and partnering with the Hy-Tek Design Teams ensures a Better Operations Design.