Harness the Potential of Cobots

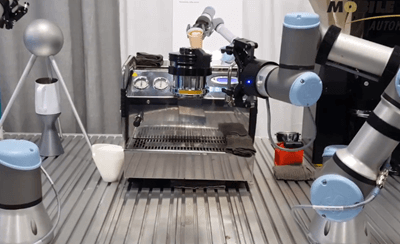

In the 1960’s robotic arms first became mass-produced for factory automation and were caged off for safety concerns. Decades later, collaborative robotic arms use a variety of techniques to safely work alongside humans. For most of the current collaborative arms, speed is limited so that the force of an impact can be controlled. With advancements to vision systems, there are ways to use predictive software that can safely stop in time from having a collision without sacrificing speed.

Our Solutions

- Low Capacity

- Moderate Capacity

- High Capacity

- High Capacity

Universal Robots UR3

The Universal Robots UR3e is an ultra-lightweight, compact collaborative industrial robot, ideal for table-top applications. Its small footprint makes it ideal to be built directly inside machinery or in other tight workspaces. This cobot weighs only 24.3 lbs (11 kg), but has a payload of 6.6 lbs (3 kg). Its ±360-degree rotation on all wrist joints, and infinite rotation on the end joint, makes it well-suited for light assembly and screwdriving applications.

TECH CONSIDERED

- Capacity: 3kg / 6.6 lbs

- Reach: 500 mm / 19.7 in

Universal Robots UR5

The Universal Robots UR5e is a lightweight industrial collaborative robot built for medium-duty applications (up to 5 kg). This general purpose robot was built with versatility and adaptability in mind. The UR5e is designed for seamless integration into a wide range of applications.

TECH CONSIDERED

- Capacity: 5kg / 10 lbs

- Reach: 850 mm / 33.5 in

Universal Robots UR10

The Universal Robots UR10e is an extremely versatile collaborative industrial robot arm with its high payload (10kg) and extended reach capability. Its 1300mm reach spans wide workspaces without compromising precision or payload performance. UR10e addresses a wide range of applications in machine tending, palletizing, and packaging.

TECH CONSIDERED

- Capacity: 10kg / 22 lbs or 16kg / 35.3 lbs

- Reach: 1300 mm / 51.2 in

Universal Robots UR16e

The Universal Robots UR16e delivers an impressive 16kg (35.3 lbs.) of the payload within a small footprint. It is ideal for use in heavy machine tending, material handling, packaging, and screw and nut driving applications. This powerhouse robot allows for the heavier end of arm tooling and multi-part handling and is especially useful for achieving shorter cycle times.

TECH CONSIDERED

- Capacity: 10kg / 22 lbs. or 16kg / 35.3 lbs

- Reach: 1300 mm / 51.2 in