Scale Business Operations The Right Way

The Realtime360 Robotics™ automated solution provides intuitive, reliable, efficient robotic solutions that meet the needs of both standards, repetitive robotic applications as well as unique, customized applications.

Key Features

01

Flexible control integration with most common robot manufacturers

02

ABB System Integrator

03

Customizable for unique applications

04

Available for standard applications

05

A wide range of end-of-arm tools, including single and multi-function units, is based on the ever-changing application requirements.

06

Automatic change over for different products/functions.

07

Interfaces seamlessly with our entire Realtime360 Suite, including the Realtime360 WES and Realtime360 WCS.

08

Configurable to communicate with most third-party Host systems.

Benefits

- Robots can automate tedious and unsafe tasks, enhance efficiency, quality and flexibility.

- Increases performance and productivity.

- Low maintenance costs & reduces operators errors.

- Reduces common injuries due to repetitive tasks.

- Flexible and Scalable – Expands and adapts to easily accommodate future change and growth.

- Reduces operating costs.

- Reduces manpower demand through automation.

- Saves floor space within your facility.

Ideal Applications

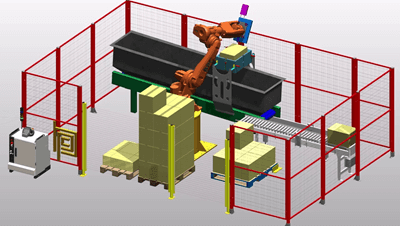

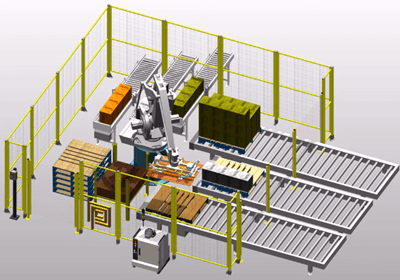

Case Palletizing

Bag Palletizing

Robotic Depalletizing

Scrap Metal Palletizing

Mixed Load Palletizing

Watch Robotic Palletizers in Action

Our AMR partner Videos

Looking to Increase Performance?

Jump Start Your Productivity.

This white paper will help you discover which picking solution is right for you.