How to Prepare Your Operation for the Busiest Time of the Year — Without Breaking Down

Insights by Chris Henkel, Hy-Tek Intralogistics Lifecycle Services Team

Introduction: Turn Peak Pressure into Peak Performance

As peak season approaches, warehouses face a familiar but formidable challenge: how to meet surging demand without compromising performance. With labor shortages, aging infrastructure, and rising customer expectations already testing operations, your peak season rush can feel like a stress test your facility isn’t ready for.

But it doesn’t have to be that way.

This strategic guide walks you through a proven approach to peak season readiness—one that doesn’t rely on last-minute fixes or costly overhauls. Instead, you’ll discover how to build resilience through data-driven audits, workforce optimization, and smart technology integration. Whether you manage a single distribution center or a multi-site network, you’ll find practical, scalable insights designed to help your operation thrive under pressure.

Executive Summary

- Peak season places exceptional strain on warehouse operations already burdened by labor shortages, cost pressures, and aging infrastructure.

- This guide outlines how to prepare for peak by optimizing labor, systems, and workflows through proactive assessments and strategic improvements.

- Built for warehouse and distribution leaders, it offers actionable steps to reduce risk and boost performance before, during, and after peak season.

Section 1: Understanding the Pressure

The State of the Warehouse Heading into Peak

The lead-up to peak season often reveals cracks in the operational foundation. Many facilities are already battling:

- Labor shortages and rising wages

- Aging equipment and infrastructure

- Volatile inventory levels and limited space

- High service level expectations with low tolerance for errors

- Seasonal volume spikes that leave no margin for unplanned downtime

Section 2: Readiness Starts with Risk Awareness

Audits and Assessments for Proactive Planning

The most effective way to prepare for peak isn’t by working harder—it’s by working smarter. Hy-Tek’s Peak Readiness Program is designed to identify and address vulnerabilities before they impact operations. The program includes:

- Maintenance Process Audit — Optimize preventive maintenance and improve CMMS usage

- Equipment Health Assessment — Flag high-risk components and prioritize replacements

- Technician Proficiency Audit — Evaluate team readiness, uncover skill gaps, and recommend training

- Inventory & Spare Parts Review — Confirm availability of critical components with long lead times

- Escalation Protocol Review — Define action plans for high-risk failure scenarios

Section 3: Meeting SLAs Under Pressure

Order Prioritization and Fulfillment Accuracy at Scale

With SLAs on the line and customer expectations rising, speed alone isn’t enough—you need accuracy and agility, too.

- Define SLA tiers and align WMS/WES logic to support prioritization

- Use wave and batch picking to streamline high-priority order fulfillment

- Implement system slotting and dynamic replenishment to maintain flow

- Train teams to handle exceptions before the rush begins

Section 4: Operational Optimization During Peak

Smart Adjustments for Real-Time Efficiency

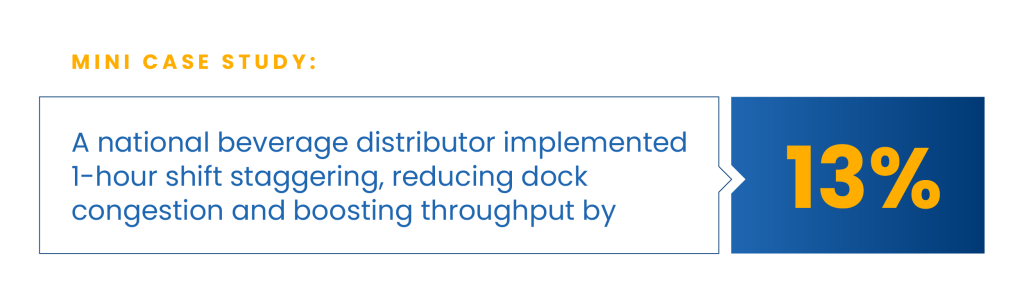

Even the best-laid plans require flexibility. Real-time operational tuning can drive significant improvements during peak weeks.

- Optimize shift and break schedules to balance throughput and fatigue

- Stagger inbound and outbound windows to reduce dock congestion

- Establish high-speed pick zones in bottleneck-prone areas

- Detrash at receiving to free up space and accelerate putaway

Section 5: Continuous Improvement Starts Post-Peak

What You Learn This Year Powers Success Next Year

The end of peak is the beginning of your next advantage. Post-season analysis is where short-term wins turn into long-term gains.

- Conduct post-peak audits and collect technician feedback

- Benchmark KPIs across functions to identify top- and low-performing areas

- Update SOPs and training materials based on real-world challenges

- Reassess spare parts strategy using actual failure data

- Partner with Hy-Tek for automation tune-ups and modernization planning

Section 6: Building Resilience with the Right Technology

Automation and Software That Scale with Demand

Technology should empower—not overwhelm—your operation. Hy-Tek helps future-proof your facility through scalable, right-sized solutions.

- Hy-Tek IntraOne® Orchestration — Seamless WMS/WES/WCS integration

- Robotic Systems — AMRs, AS/RS, and sortation to boost efficiency

- 24/7 Remote Monitoring — Minimize response times and reduce downtime

- Modular Retrofits — Extend the value of your current infrastructure

Section 7: Q&A with the Hy-Tek Lifecycle Team

Q: How early should we start peak readiness planning?

A: Ideally, 10–12 weeks before peak. This allows time for assessments, ordering parts, training technicians, and building contingency plans.

Q: Will Hy-Tek audits disrupt daily operations?

A: No. Our team integrates seamlessly with your existing workflows to avoid interruptions.

Q: What types of facilities benefit most?

A: Hy-Tek supports single-site DCs, multi-site networks, and highly automated operations across retail, 3PL, healthcare, and beverage sectors.

Q: Can Hy-Tek help implement improvements?

A: Absolutely. We offer full support—from diagnostics and planning to on-site service and emergency response.

Conclusion: Be Ready, Not Reactive

Peak season isn’t about adding more people or equipment—it’s about making smarter use of what you already have. With Hy-Tek, you gain the tools, insight, and support needed to turn seasonal pressure into peak performance.

Ready to optimize your peak strategy?