Introduction: Why Warehousing Needs a Smarter Strategy

The supply chain is at a crossroads. Rising labor costs, persistent staffing challenges, and growing customer expectations for speed and accuracy are putting unprecedented pressure on warehouses and distribution centers. At the same time, technology is evolving faster than most organizations can adapt. Robotics, artificial intelligence (AI), digital twins, and advanced simulation are no longer experimental tools—they are proven drivers of resilience and return on investment (ROI).

AWS and Hy-Tek Intralogistics’ IntraOne have partnered to create a unified warehouse platform that not only addresses today’s operational challenges but also builds a foundation for future growth, scalability, and mergers and acquisitions (M&A) readiness. This blog explores how their combined approach transforms fragmented supply chain operations into harmonized, intelligent, and future-ready networks.

Breaking Down Barriers: The Challenge of Fragmented Systems

The Traditional Warehouse Tech Stack

For decades, warehouses have relied on three main types of software systems:

- WMS (Warehouse Management System): Manages inbound, outbound, and inventory processes.

- WCS (Warehouse Control System): Oversees conveyors, sortation, and print-and-apply stations.

- WES (Warehouse Execution System): Orchestrates robotics, balances workloads, and optimizes automation.

The problem? These systems are often sourced from different vendors, each with unique interfaces and integration requirements. This creates:

- Data silos that limit operational visibility

- Costly custom integrations to bridge systems.

- Conflicting vendor support during outages or issues

- Maintenance headaches as upgrades compound complexity.

Why Fragmentation Limits Growth

For organizations trying to scale, fragmented systems are more than a technical challenge – They are a strategic roadblock. They delay the adoption of automation, increase operational risk, and make it harder to manage labor effectively.

Strategic Planning for the Future Warehouse

Why Planning is Critical

Warehouses face pressures on multiple fronts:

- Rapid technological advancements that demand continuous adaptation.

- Rising labor costs and shortages that strain efficiency.

- Customer expectations for speed, accuracy, and scalability.

Without a strategic roadmap, investments in automation risk becoming obsolete or failing to deliver meaningful ROI.

Data-Driven Preparation

The process starts with upfront data gathering:

- Inventory profiles

- Order volumes

- SKU velocity

- Labor metrics

These data points shape decisions about whether to pursue a greenfield site (a new facility with total freedom but higher capital needs) or a brownfield retrofit (faster deployment but with existing constraints).

Think at the Network Level

Leading organizations also expand planning beyond the facility. Network-level design ensures that distribution centers work together to optimize service levels, reduce costs, and balance capacity across the supply chain.

Reducing Risk with Simulation and Digital Twins

The Role of Simulation

Simulation mirrors the physical warehouse in a digital environment. This allows organizations to run “what-if” scenarios, testing how throughput, labor allocation, or new equipment would perform before committing resources.

Digital Twins for Real-Time Decisioning

Digital twins extend simulation into the real world. They create a bi-directional link between actual facilities and their digital counterparts, enabling:

- Real-time visibility

- Predictive maintenance

- Continuous optimization

- Data-driven decision-making

Together, simulation and digital twins provide the confidence organizations need to make capital investments with reduced risk and clear ROI forecasts.

would perform before committing resources.

Digital Twins for Real-Time Decisioning

Digital twins extend simulation into the real world. They create a bi-directional link between actual facilities and their digital counterparts, enabling:

- Real-time visibility

- Predictive maintenance

- Continuous optimization

- Data-driven decision-making

Together, simulation and digital twins provide the confidence organizations need to make capital investments with reduced risk and clear ROI forecasts.

Technology as the Enabler of Transformation

Artificial Intelligence and Machine Learning

AI and machine learning enable systems to think, act, and react autonomously—improving quality, reducing labor needs, and automating workflows.

Examples include:

- Computer vision for quality inspection

- Predictive maintenance alerts

- Layout optimization algorithms

Robotics and Automation

Robotic systems now handle 60–80% of outbound fulfillment tasks in many applications. From autonomous mobile robots (AMRs) to advanced putwalls, automation reduces manual labor while improving accuracy and speed.

3D Modeling and IoT for Warehouse Intelligence

- 3D LIDAR scanning captures facilities in precise detail to inform system design.

- IoT sensors connect equipment and systems, ensuring synchronized, real-time data flow.

This layered ecosystem turns the warehouse into a smart, adaptive operation.

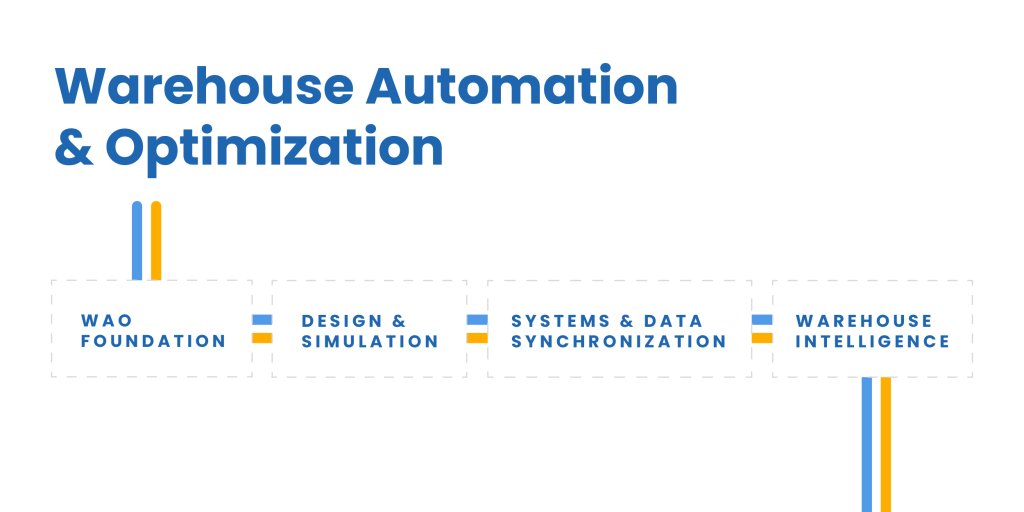

WAO: Amazon’s Blueprint for Warehouse Automation ROI

Amazon’s Proven Playbook, Now Available Through AWS

Amazon’s fulfillment centers set the benchmark for global speed and scalability. Through AWS, that expertise is now accessible to enterprises via WAO—Warehouse Automation & Optimization.

WAO Framework: A Step-by-Step Approach

WAO delivers a structured, modular roadmap for warehouse transformation:

- Survey & Model: Capture the facility using LIDAR scanning and create a digital baseline.

- Simulation & Analysis: Test future scenarios, validate throughput, and optimize workflows.

- Systems Synchronization: Connect siloed systems into a unified platform.

- Intelligence Layer: Deploy AI, digital twins, and advanced analytics.

- Foundation Build: Implement technology in phases to minimize disruption.

ROI Outcomes with WAO

Organizations leveraging WAO achieve measurable improvements:

- 20% better space utilization

- 25% transportation cost reduction

- 15% On-Time In-Full (OTIF) improvement

- 30% faster inventory turns

- 55% lower off-site storage and 3PL costs

- 25% reduction in global trade costs

Delivering Harmony with IntraOne: One platform, complete control

Simplifying Operations Through Integration

Hy-Tek’s IntraOne platform eliminates silos by unifying WMS, WCS, and WES functionality into a single web-based interface. Key benefits include:

- Unified dashboards with real-time visibility.

- Cloud-based, no-code automation.

- Common APIs for seamless integration.

- Scalable design for conventional and automated warehouses alike.

Why it Matters

By replacing fragmented vendor solutions with IntraOne, organizations can reduce complexity, lower costs, and prepare for future growth.

People + Technology: The Human Side of Automation

Balancing People and Technology

Technology alone doesn’t solve the labor challenge. Strategic planning must also consider the workforce:

- Forecasting labor savings and reassignments.

- Upskilling employees to work with automation.

- Implementing change management strategies to ensure adoption.

- Improving worker safety and satisfaction through ergonomics and reduced manual strain.

When people and machines are aligned, organizations create resilient, future-ready operations.

From Vision to Reality: The Innovation Lab

To help organizations see these solutions in action, Hy-Tek and AWS host demonstrations in the Innovation Lab in Erlanger, KY.

Here, businesses can:

- Test robotics systems.

- Explore simulation and digital twin technology.

- Experience IntraOne’s unified platform.

The lab bridges the gap between concept and execution, providing decision-makers with real-world validation before investing.

Conclusion: A Unified Future, Ready to Deliver ROI

The warehouse of tomorrow will not be defined by siloed systems. It will be unified, data-driven, and powered by AI, robotics, and digital twins. Organizations that plan strategically, validate decisions through simulation, and adopt platforms like IntraOne will achieve measurable ROI while building resilience for the future.

AWS and Hy-Tek are committed to guiding that journey—from facility design and network optimization to workforce planning and technology rollouts.

Next Steps: Start Your Transformation

- Visit the Innovation Lab in Erlanger, KY, to see the future in action.

- Learn more about IntraOne software and its full-stack capabilities.

- Subscribe to the Automation Insider podcast on Apple or Spotify for insights from industry leaders.

The time to unify your warehouse is now.