It’s no secret that managing e-commerce and omnichannel order fulfillment operations have become increasingly difficult over the past few years.

Today, the Supply chain faces strain to keep up with not only the demand for products but to ship them in a timely manner to keep customer confidence and loyalty. A study reported that 46% of global shoppers expect to receive their online order within two to three days.

Many companies have started to examine their warehouse operations for cost-saving opportunities as well as quick ways to improve efficiency and productivity.

So, let’s talk about one method for doing this, known as advanced cartonization.

What is Cartonization?

Cartonization is the process of finding the best way to package items for shipping. By evaluating the size, shape and weight of each item, cartonization can speed up order delivery and increase profitability.

How is Advanced Cartonization Different?

Imagine a warehouse, pickers are on the floor going from location to location picking one or two orders into totes. When complete they walk to a pack station and drop off the materials to be packed and ship. Rinse and repeat.

This strategy requires a lot of labor and can lead to unacceptable error rates. There is also a good chance the company is losing money in shipping by not taking advantage of the dimensional (DIM) weight protocols.

Using advanced cartonization (also called pick to box) in a warehouse can take the guesswork out of the DIM weight rules before a single item is picked.

Using a warehouse management system (WMS software), the system analyzes the size, weight and dimension of items to be picked and directs the picker to the appropriate box to select. It also rate shops the shipping companies to get the best rate, while still meeting customer expectations.

The system prints out the shipping label to be placed on the box, again, all before a single pick. (Note: you can have the label placed on the box at the end of your picking process as well to avoid unused label costs. Some carriers charge when you print, others charge when you ship, so make sure you are aware and avoid being double charged on labels).

The picker then fulfills all the orders with a mobile picking cart with the pre-labeled boxes on it, now picking 20 to 30 orders in the same time it took to pick one or two.

The method also effectively eliminates the need for packing stations as well as significantly decreases shipping costs and error rates. One of our clients saw an almost $500K saving each year in freight and labor costs.

Complexity can make cartonization tricky. For example, if you are mixing items in a carton the durable goods should be placed at the bottom of the order, and fragile items should go on top. Cartonization can do this, but your solution might need to factor in several real-time decisions such as nesting, stacking, not mixing certain items, and understanding what to box and what items might need to go in envelopes.

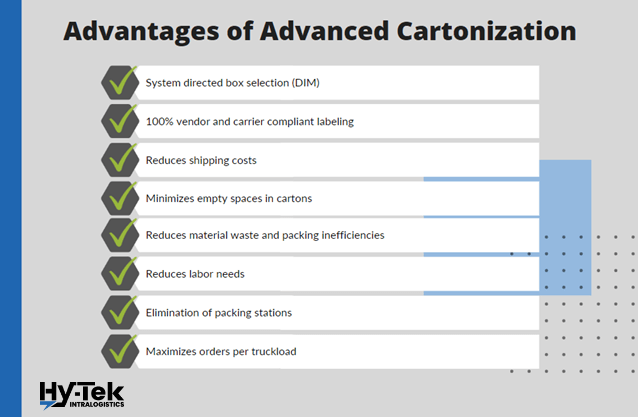

Ways Advanced Cartonization Makes Order Fulfillment More Efficient

- System-directed box selection

- 100% vendor and carrier-compliant labeling

- Reduces shipping costs

- Minimizes empty spaces in cartons

- Reduces material waste and packing inefficiencies

- Reduces labor needs

- Elimination of packing stations

- Maximizes orders per truckload

- Give you the ability to pack orders together (EX: You order items from Amazon on Monday and add another item Tuesday to a separate order. The system can understand that the order is going to the same shipping address and can cartonize them together).

What Types of Warehouses are Best Suited for Advanced Cartonization?

- E-commerce/Omnichannel orders

- Warehouses that have a high amount of orders that go out daily

- If you struggle with job retention and hiring on the warehouse floor

- Split case or small piece picking (B2C and direct to customer)

Potential Challenges to Implementing a Cartonization System in your Warehouse Operation

- Capturing the dimensions of your items

- Maintaining your dimensional information for any new products

- Applying mixing rules for items that should not be packaged together

- Understanding what items should always be boxed and what items should go in envelopes based on certain measurables

How to Get Started with Advanced Cartonization

Say you own a small retail business that ships out orders of clothes and other small items.

Currently, you have a packing station where employees pack each order into a box by hand. However, you are having difficulty retaining staff to work the packing station which is causing delayed orders and other inefficiencies.

After doing some research, you’ve decided that advanced cartonization is the best option for your business. You purchase the necessary equipment to tie into your WMS and create a plan for how the items in your inventory will be arranged in boxes.

Over the next several weeks you collect data on average order sizes, weights, items, etc. Then you use these data points to find how the total volume of your orders correlates with the number of cartons prepared by your warehouse pickers, accounting for any outliers.

With time, your new cartonization system will begin to learn programmed algorithms and, thanks to machine learning, your packing efficiencies will gradually improve as you cut down the number of touches throughout your fulfillment process.

The new cartonization system lets you not only pack orders faster but more efficiently too – all while cutting down on the amount of staff you need to retain and hire. Your business has never run this smoothly, and you are significantly improving your bottom line.

FAQ

What does cartonize mean?

Cartonize is the process of packing items into boxes for storage or shipment.

What is cartonization?

Cartonization is the process of finding the best way to package items for shipping while reducing unused space. By evaluating the size, shape and weight of each item, cartonization can speed up order delivery and increase profitability.