A warehouse management system (WMS) is a software program that helps companies manage their warehouse operations throughout the entire fulfillment process. This includes tracking goods and materials as they enter the warehouse to shipping them out.

In our hyper-connected world, customers expect their online orders to be delivered fast and accurately. To meet these expectations, businesses need to have a well-organized warehouse with an efficient inventory system. This is where a WMS is pivotal for your business. By tracking all the materials within the warehouse, businesses can save time and improve accuracy when picking and shipping orders. In addition, a WMS can automatically mark the progress of each order so that customers can be informed in real-time on the progress of their order. As a result, a WMS can help businesses keep their customers happy by providing them with the visibility and speed they demand.

Understanding Warehouse Management System (WMS)

You can think of a warehouse management system as the glue that binds together all the different processes and information within a warehouse. Without a WMS, detailed reports and transparency into real-time space, inventory, and labor are not possible.

What Does a WMS Do?

A warehouse management system is a software application that helps organizations with inventory management and distribution operations. In other words, it helps companies keep track of all their inventory and make sure it gets where it needs to go.

In addition to managing inventory, WMS also helps with work creation and execution for labor, as well as reporting and analytics for real-time visibility into equipment, order status, and labor execution.

By tying into labor management systems, a WMS can provide richer productivity tracking and workforce planning. And by integrating with warehouse control systems (WCS) and warehouse execution systems (WES), a WMS can be instrumental for processes that involve automated material handling processes.

Featured Resource

[Free Download] WMS Questionnaire

Questions to guide you in your WMS selection process.

No strings attached. Free download.

How Does a WMS Work?

WMS has gone through several evolutions since its inception, from physical client servers and manual entry systems to a comprehensive software platform that can be cloud-based with remote, web-based access. The platform is generally implemented and maintained by the company that created it.

Businesses choose which applications and features they want to use. Then, the WMS provider configures various supply chain processes and functions such as inventory and order management, labor management, transportation management, and reporting.

Once all the processes are configured to the system, data is collected on the server and becomes available to those with permission. Reports can be generated with metrics, graphs, or other visuals that a client might need to determine how the business and its departments are performing.

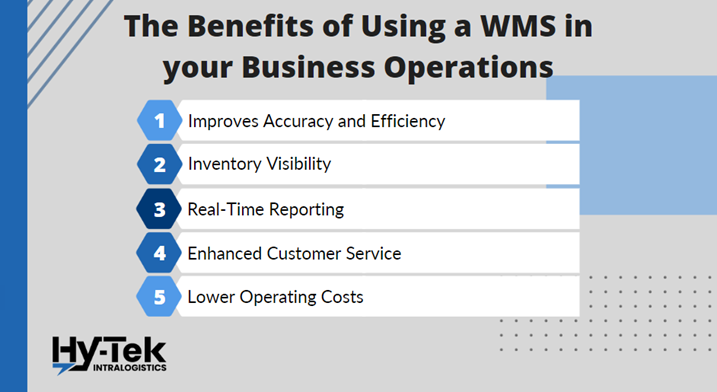

What are the Benefits of Using a WMS in your Business Operations?

Businesses employ warehouse management systems for various reasons, such as lowering operating expenses, streamlining warehouse operations, automating tasks, and improving supply chain management. Although the benefits companies seek may differ, some notable ones are as follows.

1. Improves Accuracy and Efficiency

WMS presents various improvements in the warehouse in terms of accuracy and efficiency.

Amongst these, quality control checks are very valuable because they ensure that only the products that meet the required standards are shipped to customers. This improves customer satisfaction and reduces cycle counts.

Additionally, generating pick lists and pick routes creates an efficient process for workers to follow when collecting items from the shelves. By having a set route and list, employees waste less time guessing where items are located or in which order to collect them.

2. Inventory Visibility

Warehouse management systems can be a real lifesaver when it comes to keeping track of your inventory levels.

By scanning items with RFID tags and using location tracking, you can avoid losing any products – or worse, running out of them.

With the help of an enterprise resource planning (ERP) system, you can also keep track of how different products are performing so you can make better decisions about what needs to be ordered and when. Learn the key difference between ERP vs WMS and how they can work together.

All of this helps to keep your stock situation under control which is great for both avoiding stock-outs and ensuring that you always have the right products on hand.

3. Real-Time Reporting

A well-functioning WMS delivers plenty of advantages for a company. Not only can it provide accurate and up-to-date information on things like shipments, orders, and inventory levels, but it can also generate reports regularly.

This is extremely helpful for companies who want to stay on top of their operations and make sure that everything is running smoothly. Additionally, a well-built WMS can be scheduled to automatically update and generate alerts, which means that you can always be confident that you are getting the most up-to-date information possible.

4. Enhanced Customer Service

A warehouse management system can help reduce inventory paperwork and improve order-to-delivery processes. You can maintain reports, pick tickets, and move tickets and packing lists electronically.

This means that you can give more accurate delivery dates to your customers, reducing the level of customer complaints.

5. Lower Operating Costs

A WMS can help your business save money by reducing waste and maximizing space utilization. Additionally, it can help identify which units to pick first, when to push sales, and calculate the optimal location and travel times for each item.

By allocating fewer people to each part of the supply chain, a WMS allows your business to be more effective overall.

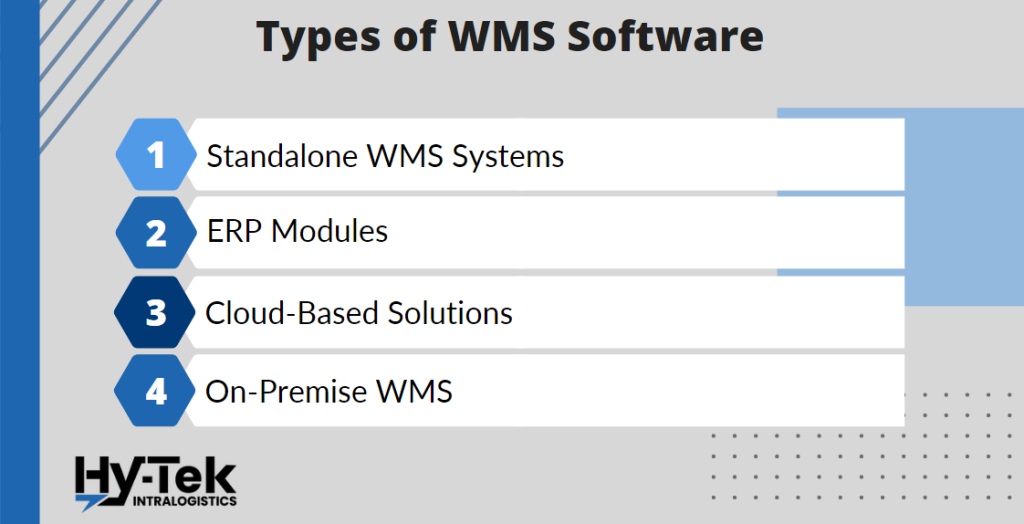

Delivery Options of WMS Software

There are different types of WMS software, each with its own advantages and disadvantages.

- Standalone WMS is a type of on-premise software that has standard features placed on the company’s local hardware and network. Many WMS programs are third-party packages that must be integrated with the rest of the company’s management software (such as the ERP system). Standalone WMS is often used by small businesses because it is less expensive and easier to implement than enterprise WMS.

- ERP Systems are designed to be a comprehensive solution for tracking all company resources. This includes everything from human resources and sales to marketing and finance. ERP systems are also often used to track customer relationship management (CRM) data. Some even include a Supply Chain Management (SCM) or Warehouse Management System (WMS) module. In other words, ERP systems are pretty much the one-stop shop for tracking everything that happens in a business. This makes them a good fit for businesses of all sizes with a wide range of client requirements.

- Cloud-based WMS Systems are web-based and centralized computing using cloud technologies. They are perfect for businesses of all sizes because they don’t require installation or synchronization with native hardware or networks. Additionally, cloud-based warehousing applications are scalable, and development happens quickly. These systems provide the same design and functionality as on-premise WMS systems, but updates, hosting, and support of the system come from your WMS vendor.

- On-Premise WMS are managed and hosted in-house. The core difference between a cloud-based and on-premise WMS is the on-premise puts you and your IT and development team in full control with the option to have additional maintenance and support provided by your vendor.

One notable factor to take into consideration when looking at the software systems required to run your warehouse is choosing a provider that offers a single platform for all your software needs. There are many benefits to using a single cohesive system instead of several disparate ones. When using a single software platform, the implementation and maintenance of your integrations are fewer and more cohesive, and visibility to data is in one place instead of bouncing in and out of separate systems providing holistic control over your entire operation.

Three signs that you need WMS Software

If you find yourself regularly muttering, “where did I put that?” or “I could have sworn it was here a minute ago,” you may need WMS software. Here are three signs that it’s time to invest in a warehouse management system:

1. You suffer from disorganization in your warehouse (products are misplaced, lost, expired, or damaged more frequently than desired).

2. You perform physical inventory counts that shut down your entire warehouse operation more than three times per year.

3. There is an increasing or a high rate of order errors and customer complaints.

If any of these sound familiar, it’s time to take a closer look at WMS software. A good warehouse management system can save you time and money by improving efficiency and reducing errors. It can also help to boost customer satisfaction by ensuring that orders are filled correctly and on time. So if you’re ready to stop losing things and start making money, it’s time to invest in WMS software.

How to choose the right WMS for your business

When it comes to choosing a warehouse management system (WMS), there’s no one-size-fits-all solution. The right WMS for your business will depend on several factors, including the size and type of your operation, your budget, and your specific needs. To find the best fit for your business, it’s important to do your homework and evaluate your options carefully. Here are a few things to keep in mind as you shop around for a WMS:

1. Size and Complexity

The first thing to consider is the size and complexity of your operation. If you have a small, straightforward operation, you probably don’t need a complex, feature-rich WMS. On the other hand, if you have a large, multi-site operation with multiple warehouses and inventory types, you’ll need a more robust system that can handle that level of complexity.

2. Budget

Fortunately, there are WMS solutions available at every price point. However, it’s important to remember that you get what you pay for. Cheaper solutions may be missing important features or be less reliable than more expensive options.

3. System Requirements and Pain Points

Not all warehouse management systems are created equal. Some are designed for specific industries or types of products, while others are more general purpose. There are different tiers of WMS’s that vary in complexity and functionality, however there are some basic WMS functional requirements that any WMS should have.

4. Support

Once you’ve chosen a WMS, you’ll need to make sure the support hours match your needs. Most businesses desire vendors that provide a 24/7 support staff that is readily available during peak seasons and holidays. Also, check how support is handled. Is it an email ticketing system? A call center? Livechat? Having options that will work best for your team’s needs will be important when assessing vendors.

5. Training and On-boarding

A good warehouse management system can save you time and money, but only if your employees are properly trained in how to use it. Key areas to plan for are change management plans, implementation team and power users, and training methods (such as: hands-on walk-throughs, online learning, and on-site demos). Be sure to factor training costs into your overall budget when considering different WMS solutions.

Three WMS Implementation Challenges for Businesses

Implementing a warehouse management system (WMS) can be a daunting task for any business, large or small. Here are three of the most common challenges we see businesses face when implementing a WMS.

1. Data Migration

When switching to a new WMS, businesses need to migrate their existing data (such as product information, customer orders, and supplier information) into the new system. This can be a time-consuming and error-prone process.

2. Change Management

Implementing a new WMS can require changes to business processes and employee roles. For example, employees may need to be trained on how to use the new system. This can be a challenge for businesses, as it requires careful planning and execution.

3. System Integration

A WMS needs to integrate with other business systems, such as accounting and order management systems. This can be a complex process, and it is important to ensure that all systems are compatible with each other.

With careful planning and execution, businesses can overcome these challenges and reap the rewards of a successful WMS implementation.

Conclusion

If you’re still not sure if warehouse management software is the right choice for your business, ask yourself these three questions. First, do you have multiple locations or warehouses? Second, does order fulfillment take more than one day to complete? Third, are there discrepancies between your inventory expectations and what is actually there? If you answered yes to any of these questions, it might be time to invest in a WMS. And don’t worry – we can help make the transition as smooth as possible. Contact us today to learn more about our warehouse management systems and how they can benefit your business.

FAQ

What is the Meaning of a Warehouse Management System?

A warehouse management system (WMS) is a software program that helps companies manage their warehouse operations throughout the entire fulfillment process. This includes tracking goods and materials as they enter the warehouse to shipping them out.

What is the main objective of the Warehouse Management System?

The main objective of a Warehouse Management System is to help businesses move goods through their warehouse most efficiently and cost-effectively.

What are the different types of Warehouse Management Systems?

There are four different types of warehouse management systems. The most widely used types of WMS are standalone systems, ERP modules, cloud-based solutions, and on-premise systems.

What are the key features of a Warehouse Management System?

· barcode and RFID scanners compatibility

· providing real-time data streaming

· inventory location recommendations

· picking and packing options

· product tracking

· warehouse layout planning

· labor management

· yard and dock management

· kitting

· Interactive dashboards