Increase Your Efficiency and Accuracy

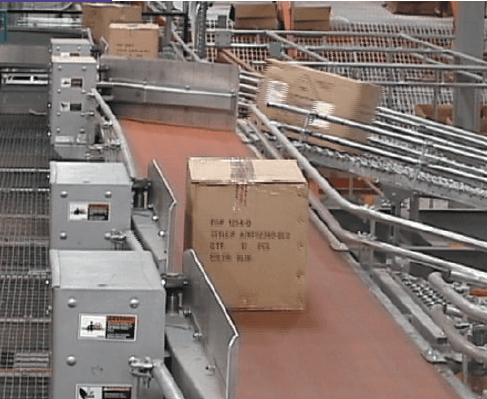

Sortation solutions can be as simple or complex as you need. They reliably automate manual sifting, categorizing, separating, dividing, and distribution tasks for greater efficiency in your distributing center operations and establish flexibility for growth. The sortation solutions are designed to support growing order demand, increased shipping accuracy, and more frequent shipments.

Our Carton Sortation Solutions

Shoe Sorters

Shoe Sorters provide a positive divert for applications requiring a wide range of product weights and sizes on the same system. With possible divert rates of over 200 cartons per minute, shoe sorters are also an excellent fit for high throughput applications. Shoe Sorters transport product on aluminum slats and sliding shoes angled at 17, 22, or 30 degrees to push the product onto take-away lines.

Activated Roller Belt Sorters

Activated Roller Belt (ARB) Sorters use plastic belting with embedded rollers to provide gentle and precise sorting of various items. ARB Sorters can sort bi-directionally, at 30 degrees and 90 degrees. Because of their unique technology, ARB Sorters are the perfect fit to divert poly bags.

Narrow Belt Sorters

Narrow Belt Sorters are an excellent option for sorting small to medium cartons at rates up to 175 cartons per minute. Narrow Belt Sorters use multiple narrow belts to transport product and 30 or 90-degree pop-up rollers mounted between the narrow belts to divert product.

Arm Sorters

Bow Arm, Trap Arm, and Flat Faced Arm Sorters provide a positive divert in lower rate applications. Arm sorters are great for diverting large items that other sortation types struggle with.

Wheel Sorters

Wheel Sorters use pop-up or steerable wheels to divert products. Wheel Sorters are an economical solution for a system that requires a medium-rate application.

Bombay Sorters

Bombay Sorters sort items that are too small or lightweight for traditional sortation methods. Bombay sorters use a “trap door” style carrier traveling on a continuous loop to drop items into sort locations.

Our Unit Sortation Solutions

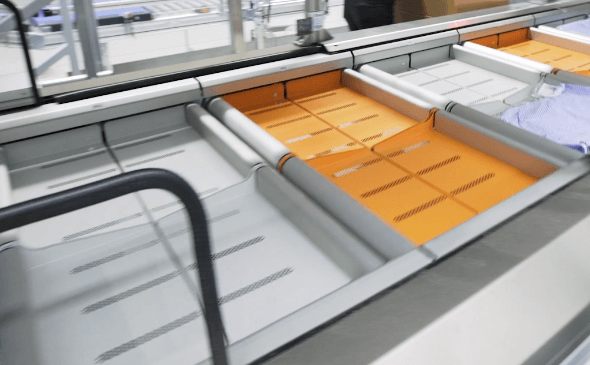

Tilt Tray Sorters

Tilt Tray Sorters are an excellent fit for sorting a variety of soft goods and small pieces at a high rate. Tilt Tray Sorters utilize tilting product carrying trays traveling on a continuous loop to divert pieces into chutes for order consolidation.

Cross Belt Sorters

Cross Belt Sorters are used to sort small items, including apparel, cartons, and high friction items, at a high rate. Cross Belt Sorters use small, bi-directional conveyor sections mounted to a continuous loop to divert products into a chute.

Bombay Sorters

Bombay Sorters sort items that are too small or lightweight for traditional sortation methods. Bombay sorters use a “trap door” style carrier traveling on a continuous loop to drop items into sort locations.

Pusher Sorters

Pusher Sorters use a pusher attached tray traveling in a continuous loop to sort small items. Pusher Sorters can be installed in a traditional “racetrack” layout or in an over / under layout to help keep space usage to a minimum.

Robotic Sortation

The Robotic Sortation solution utilizes tSort robots with a cross belt or tilt tray sections mounted to it. These systems have no single point of failure, are fast to implement, and don’t rely on a set linear path to sort products.