Increase Storage Density with Vertical Carousels

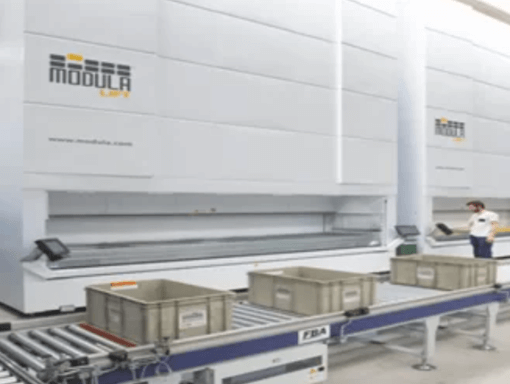

A Vertical Lift Module (VLM) is an automated storage and retrieval system used in warehouses and distribution centers to optimize space utilization and improve order picking efficiency. It consists of a tall, vertical column with multiple trays or shelves inside. The trays move up and down within the column, allowing goods to be stored and retrieved automatically by an integrated control system.

Benefits of Vertical Lift Modules

Increase Existing Space

Creating vertical storage in a small footprint is generally the first and budget-friendly move over finding and investing in a larger space. Static shelving is the solution option in this instance as it is lower cost, easy to source, ergonomic, and safe.

Quicker Access to Inventory

Are you considering the benefits of entry-level automation when evaluating the potential for vertical storage systems in your facility beyond static shelving? This is especially true in applications when the levels of small piece inventory are at least within the 300 to 400 range, and the emphasis is on quick access to all pieces.

Security of Assets

When securing high-value inventory is at stake, vertical storage systems become an ever more attractive investment. By limiting employee access (badges / IDs) to specific high-value items, this system allows for an overall improvement in accuracy and accountability.

Ensure Accuracy, Safety, and Efficency

In specialty environments where heavy or particularly awkward picking is the priority, vertical storage systems are not only a clever but essential solution. This is equally valid in other environments where extremely clean or hazardous picking is a significant concern. The bottom line is that unless your company has really low inventory or unlimited space, vertical storage systems are a worthwhile investment for almost every environment. More importantly, it can combine multiple storage and handling improvements in one seamless solution.

Watch Our Vertical Lift Modules in Action

Quick Facts on Vertical Storage Systems

01

In manufacturing, return on investment (ROI) averages 5 years, but 1 to 1 ½ years ROI in distribution

02

In space and reduction of overhead (i.e. 15 people to 3 people), ROI averages 2 to 2 ½ years

03

Vertical storage has been around for 20 years, but new advantages in the software capabilities (pick to light, laser pointers, etc.) is a real reason to take another look