Insights from John Strobel, Account Executive

Picture this: your team is hustling, orders are flowing in, but somehow, productivity is stalling. Travel times are up, pickers are zigzagging across the floor, and replenishments seem endless. You may not see it, but the root of the chaos could be hiding in plain sight: your warehouse slotting strategy.

In the world of warehousing and distribution, where speed, accuracy, and space utilization can make or break profitability, warehouse slotting remains one of the most effective and underrated strategies available. Slotting isn’t just about assigning products to shelves. Done right, it aligns your storage strategy with your business goals, reducing labor costs, improving pick rates, optimizing space, and increasing overall efficiency.

At Hy-Tek Intralogistics, we’ve seen time and again how intentional warehouse slotting transforms underperforming operations into agile, cost-effective systems. Whether you’re running a high-volume e-commerce fulfillment center or a regional distribution hub, a robust slotting strategy can be the silent engine behind your success.

What Is Warehouse Slotting?

Warehouse slotting is the process of determining the optimal location for each SKU within a storage facility. The goal is to reduce travel time for pickers, balance replenishment needs, and maximize cube utilization. Slotting decisions are based on a variety of factors including product dimensions, order velocity, order commonality, and handling requirements.

More than just placing fast movers in easy-to-reach spots, warehouse slotting is a dynamic and data-driven exercise. It should evolve with your business, responding to SKU turnover, seasonal shifts, new product introductions, and customer behavior changes.

Why Warehouse Slotting Goes Out of Date

If your facility has been operating for several years without re-slotting, chances are your current layout isn’t working as hard as it could be. Order profiles change. Products come and go. Promotions drive spikes in demand. Yet many operations continue using outdated slotting strategies simply because they worked once.

This inertia leads to a gradual decline in efficiency. Travel paths get longer. Pick rates slow down. Replenishment becomes more frequent. Ultimately, labor costs increase and space is underutilized. Regularly reviewing and updating your warehouse slotting strategy is one of the most cost-effective ways to reverse this trend.

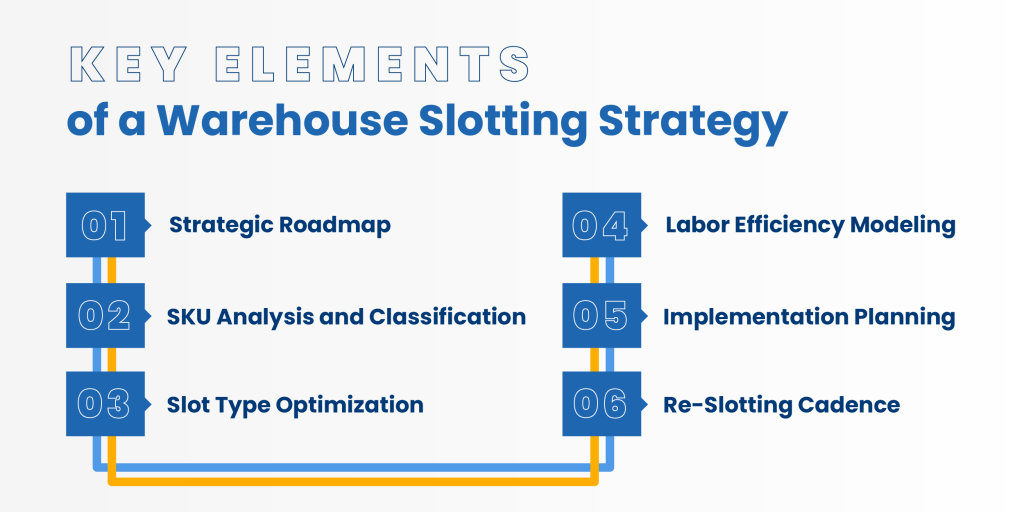

Key Elements of a Warehouse Slotting Strategy

A successful warehouse slotting plan is built on a combination of thoughtful planning, quality data, and the right tools. Here are the foundational components:

1. Strategic Roadmap

Before analyzing a single SKU, you need a clear roadmap. Define the goals of your slotting initiative. Are you preparing for peak season? Adding automation? Trying to reduce replenishment labor? Understanding the “why” shapes every decision that follows.

This roadmap should also take into account:

- Short- and long-term facility plans

- Available space and storage media

- Labor considerations

- System capabilities (like WMS or LMS integration)

2. SKU Analysis and Classification

SKU-level data is the heart of warehouse slotting. You’ll want to analyze:

- Pick velocity (daily/weekly/monthly movement)

- Cube throughput (how much space each SKU consumes over time)

- Order commonality (which items are frequently ordered together)

- Handling unit type (case, each, pallet, etc.)

Many operations use ABC classification to group SKUs by velocity: A-items are fast movers, B-items are moderate, and C-items are slow. Slotting then focuses on placing A-items in high-efficiency zones to minimize travel.

3. Slot Type Optimization

Choosing the right slot type is just as important as deciding where a product should go. The slot type should support the SKU’s cube, weight, and pick method while also balancing density and accessibility.

For example:

- Shelving and bins for small, fast-moving items

- Case flow for medium-volume products

- Pallet flow or decked racking for bulk storage

The wrong slot type can lead to excessive replenishment (if too small) or wasted space and long pick paths (if too large). Getting this balance right is key.

4. Labor Efficiency Modeling

Slotting directly impacts picker travel time and replenishment cycles. By modeling labor costs and travel paths based on proposed slotting plans, you can simulate the gains before making physical changes. Tools like Labor Management Systems (LMS) help validate whether proposed moves will deliver a return.

5. Implementation Planning

Even the best slotting plan won’t produce results if it lives in a spreadsheet. Clear execution plans are essential. This includes prioritizing changes that yield the highest impact, staging moves during low-activity windows, and engaging floor teams to ensure adoption.

Slotting changes can be disruptive, so careful rollout planning ensures productivity doesn’t suffer in the short term.

6. Re-Slotting Cadence

Warehouse slotting isn’t one-and-done. It’s an ongoing process. Your initial re-slotting effort may be the most intensive, but maintaining efficiency requires periodic reviews. As new SKUs are added and customer behavior changes, continuous improvement keeps your layout aligned with operational needs.

Quarterly or semi-annual slotting audits are often enough to keep things on track, with more frequent adjustments around peak season.

Benefits of an Optimized Warehouse Slotting Strategy

Slotting may not grab headlines like robotics or AI, but its impact is undeniable. The right slotting approach delivers measurable gains across multiple dimensions:

- Labor Savings: By reducing travel distances and touches, slotting directly lowers labor costs.

- Higher Pick Rates: Optimized pick paths improve throughput and accuracy.

- Better Space Utilization: Right-sized slots and logical grouping maximize cube usage.

- Reduced Replenishment: Properly sized pick faces reduce the need for frequent restocking.

- Improved Ergonomics: Slotting high-frequency items in ergonomic zones reduces strain and improves worker satisfaction.

- Scalability: A smart layout adapts more easily to growth, automation, or SKU proliferation.

Slotting in the Age of Automation

As automation becomes more common in warehouses, warehouse slotting becomes even more critical. Whether you’re implementing goods-to-person systems, autonomous mobile robots, or automated storage and retrieval systems, the placement of SKUs influences throughput and utilization.

For example, robotic systems thrive when fast-moving items are concentrated in zones that reduce cycle time. Poor slotting can cancel out the gains from these technologies. That’s why Hy-Tek often recommends slotting analysis as a precursor to automation projects.

Let Hy-Tek Help You Optimize Your Slotting Strategy

At Hy-Tek Intralogistics, we take a data-driven, consultative approach to warehouse optimization. Our Strategic Services team works alongside clients to design and implement warehouse slotting strategies that align with operational goals and prepare facilities for future demands.

From initial audits to full-slotting model builds and ongoing re-slotting support, we bring the tools, expertise, and industry experience needed to drive ROI through better slotting.