Did you know that there were over 4,380,000 applications for starting a new business last year? That’s over 12,000 businesses a day, 500 businesses an hour, or eight businesses every minute.

Now, this is just businesses in general and not supply chain warehouses, but the point is that our economy is growing and with that, so are businesses that need more space.

Try our free Supply Chain Improvement Plan Generator here.

If you are in the early stages of choosing a warehouse location – or want to be ready for when that time comes – read this guide to learn the nine crucial factors to consider when selecting a warehouse and setting your supply chain network up for the best results.

Factors to Consider When Choosing a Warehouse Site

- Identify Customer Locations

- Research Real Estate Options and Costs

- Check Nearby Labor Availability

- Examine the Local Infrastructure

- Outline Local Laws and Regulations

- Determine Taxation Rates and Financial Incentives

- Research Environmental Risks

- Plan for Waste Management

- Project Scalability and Future Expansion

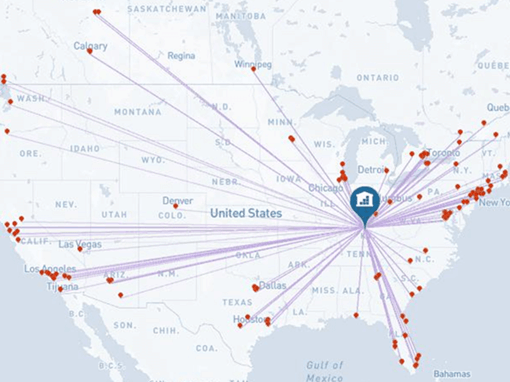

Discover Where Your Customer Base Is

First, you’ll want to determine where your customer base is.

Some questions to ask yourself are… Do we sell nationally? Do we sell to international suppliers? Is there a specific region or area where most of our target market resides? What does our customer network look like?

These questions are crucial as a first step because your business needs to be near your demand. By setting your warehouse location near your customers, you cut down your transportation costs, speed up delivery times, and even reduce inventory, which will help your business be more profitable and penetrate your market faster.

Search for Available Buildings and Compare Real Estate Rates

Now that you have a rough 200–400-mile range for where your building can be located, you’ll want to list the optimal warehouse locations and land.

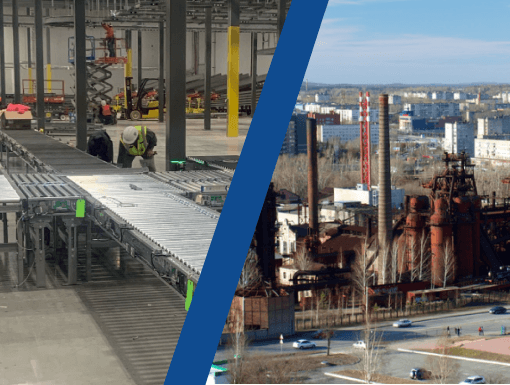

There is a significant difference in the cost to purchase an existing building versus building your plant from scratch. However, this can depend on how unique your warehouse facility is. If most existing building options need an overhaul of updates, then a greenfield site might be a better option.

Some expensive building updates to watch out for are dock updates, raising the ceilings on a building with low clear heights, electrical wiring issues, HVAC and plumbing, and roof replacements.

Check the Nearby Availability of Labor

A labor market analysis is one of the most critical steps, if not the most essential step. According to a study done by Deloitte and The Manufacturing Institute, there could be as many as 2.1 million jobs unfilled by 2030 for US manufacturing jobs.

What good does your facility do if you can’t sustain skilled workers or hire enough to hit your optimal production and utilization numbers? Thus, running a complete analysis of local demographics for the current and future workforce availability that fits the right skill sets is vital for ensuring a reliable and experienced workforce.

Review the unemployment rate, the number of workers in comparable occupations, average wage rates, and benefits within your target area for the previous five years, current market, and future forecasts at least five years ahead.

A bonus tip! Large universities and trade schools located nearby are prime for your local job market by building and maintaining a consistent talent pipeline through apprenticeships, internships, and direct hires.

Examine the Local Infrastructure

This is where a breakdown of your supply chain logistics and costs will come into play. These will be transportation costs and shipping costs across highways, railways, waterways, and air.

Find a location with good transport links for both deliveries and clients. Good connectivity between supply chain partners through highways or another mode of transportation is crucial. Trucks that are delivering oversized pallets will require easy access to your warehouse, for nearby roads and on-site.

The first thing to do is determine what mode of transportation your business will pursue for inbound shipments of raw material and outbound shipments of finished goods. An ideal warehouse location will be near your desired transportation method, have minimal traffic delays, and avoid peak traffic hours.

Outline the Local Laws and Regulations

A wide range of building codes, permitting, zoning, and environmental impact will need to be carefully priced out.

The local laws and regulations for permitting building codes are strict and vary from region to region. Hence, an excellent place to begin is with your state government site’s building codes section.

However, this step is very intensive and has yearly updates and modifications, so it is always best to review the current regulations with an environmental and/or legal support agent.

Determine Taxation Rates and Financial Incentives

Albert Einstein once said, “The hardest thing in the world to understand is the income tax.” That might be true for personal taxes, but corporate taxes are an entirely different animal.

You will want to calculate the impact of local, state, and national property taxes, along with government-driven tax credits and exemptions when it comes to business taxes.

The Tax Foundation put together a helpful study on all 50 states’ tax systems and how desirable or undesirable they are. The rankings are based on several factors such as corporate taxes, individual taxes, sales taxes, property taxes, and unemployment insurance taxes.

Below are the 10 best states:

Tax breaks and rebates vary from region to region and state to state based on a wide range of benefits businesses can offer to their local community.

However, in the United States, governments are not shy about handing out financial incentives. In fact, figures from a Princeton University research study done by Cailin Slattery and Owen Zidar estimate local and state governments spend around $30 billion per year on business tax incentives.

The most basic form of this is multi-year incentives or discounts to create new jobs.

Research Local Environmental Factors and Risks

Natural disasters are horrible and catastrophic events, and unfortunately, they are also something that you need to plan for when selecting the perfect location for your warehousing facility. Even smaller local weather conditions like flooding and high winds need to be accounted for because the environment can impact building integrity and business operations.

This is where an EPC (Engineering, Procurement, and Construction) firm will take over and review topography, geotechnical conditions, the environmental history within your area, and more to notify you of any red flags or minor issues to have on your radar.

Disposal and Waste Management

The importance of conserving our planet and reducing harmful waste continues to grow, and pollution regulations have also increased. That is why your supply chain operation must plan on two fronts.

The first is how you plan to protect your workers’ health and your plant’s impact on the local ecology.

And secondly, is having an awareness of the regulations surrounding the cost of permitting, disposal, and mitigation in your area.

ERC provides a great breakdown on how to budget for waste disposal that dives deeper into creating a disposal plan, costs associated, and potential savings.

Project Scalability and Future Expansion

Always be looking ahead. It can be easy to focus solely on your current warehousing operations, but having options in place to scale your business on-site will put you ahead when the time comes to expand.

Thus, when selecting a warehouse, think about the potential for future expansion and warehouse space at the sites you are currently considering. It’s important to properly plan and design the building space to accommodate future growth from the beginning of your network planning strategy (utilizing a consulting firm would be ideal). However, if your growth projections were a bit too conservative and you are hitting max capacity sooner than expected. You will be glad to have the option to expand the building.

Some ideas to consider:

- Can we expand the facility size (vertically and/or horizontally)?

- Can the facility handle additional storage space?

- Is there an opportunity in this area if we have future staffing needs?

- Is there additional nearby land where we can add a second facility?

- Will a greenfield, brownfield or retrofit project be best?

Conclusion

Planning out and choosing a warehouse location is an intensive process that requires careful research and analysis. You want to set your business up for success and remove any potential limitations.

Ensure that you consider all essential aspects, specifically your business goals and demands.

Taking the steps outlined will help you through your site selection process; however, most require expert consultation, experience, and connections. No matter where you are in this process, we’re here to help; contact us with any questions!

FAQ

What are Site Factors?

Site factors for selecting a warehouse include your proximity to an interstate, location to a rail line, within 30-minute travel time to a labor market and the cost of land.

What are the Characteristics of an Ideal Warehouse?

• An ideal warehouse will contain the following:

• Proper location

• Sufficient space

• Close proximity to customers

• Thorough safety regulations and training

• Proper mechanical appliances

• Optimum picking, receiving and fulfillment processes

• Updated technology and software