A recent study concluded that 68% of consumers stated that fast shipping options would make them more likely to place an order, and “fast shipping” keeps getting faster. Therefore, supply chain and micro-fulfillment center automation is becoming a necessity to meet consumer demands.

What is a Micro-Fulfillment Center?

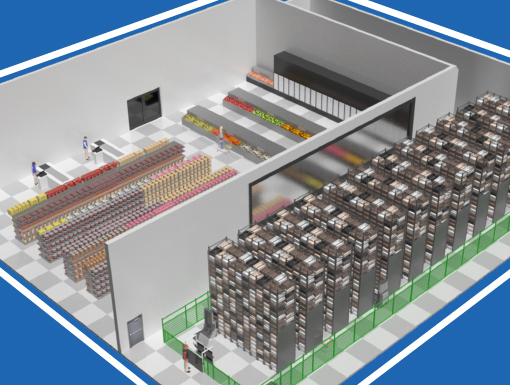

A micro-fulfillment center is a small-scale fulfillment operation that is close to the end consumer which reduces last-mile delivery costs and creates faster, more efficient fulfillment processes.

Micro-fulfillment centers are usually located in highly populated, urban areas as opposed to typical fulfillment centers which are often located on the outskirts of a city in more rural, spacious areas. The location of a micro-fulfillment center is crucial to a successful fulfillment strategy because it must be quickly and easily accessible to ensure faster pickups and deliveries to customers, sometimes within hours of the order being placed. It is suggested to perform a supply chain network optimization study where the most important factors to consider when selecting a warehouse location will be analyzed.

The push for micro-fulfillment center automation is largely driven by Amazon’s coveted two-hour delivery service and the COVID-19 pandemic which exposed weaknesses within companies’ online fulfillment processes.

Micro-fulfillment centers (MFC) are typically between 10,000 and 20,000 square feet because of the space constraints in urban areas. A smaller facility typically has lower fixed costs such as rent payments, utilities, and insurance. However, smaller footprints with less available inventory space often yield higher operating costs around replenishment labor; SKUs must be restocked more often in a micro-fulfillment center than in a large distribution center. The goal is to minimize this cost-to-serve which can be achieved by leveraging automation and technology.

By properly implementing automation and technology, one can expect improved throughput rates by as much as 60-70%, elimination of cumbersome, manual processes, and a reduction in the cost-to-serve by as much as 70%.

Choosing the right size, location, and technology for a micro-fulfillment center will depend on several critical inputs including the SKU assortment, order velocity, operation method (automated vs. manual), and delivery mode.

Types of Micro-Fulfillment Centers

Online Centers: An online center is traditionally what people think of when talking about micro-fulfillment. It is essentially a smaller-scale distribution center that is built in larger metropolitan areas with the sole purpose of fulfilling and shipping online orders for that specific region.

Dark Stores: A type of micro-fulfillment strategy is to utilize what is referred to as dark stores. A dark store is essentially a brick-and-mortar retail or grocery store that is now closed to the public and has been converted into a micro-fulfillment operation.

A dark store has aisleways just like a normal store, but instead of customers picking the items from the shelves, the fulfillment staff is picking them to put into online order packages. Once packaged, the order is ready for customer pick-up or last-mile delivery to the customer’s home. Dark-stores offer the following benefits:

- Reclaim space in the retail sector

- Fast implementation since there is no new construction required

- Utilize existing space

In-Store: An automated in-store fulfillment operation means that an operating retail store or grocery store will also have an employee-only fulfillment area to fulfill online orders. This area is typically located in the back of the store. The advantages of an in-store strategy are:

- Reduce shipping costs and faster delivery speeds since retail stores are closer to the end customer

- Speeds up store inventory turnover velocity and prevents inventory from stockpiling

- Leverage store employees for order fulfillment during slow store hours

Types of Micro-Fulfillment Center Automation

There are many different technologies to choose from when implementing a micro-fulfillment center, however, the technologies with the largest return are often associated with the automation of picking processes. This makes sense because more than 50% of total labor costs are often incurred during the picking processes.

There is a variety of picking technologies that can be utilized:

- A conveyor line that takes picked orders from an active pick area to pack stations

- Automated dispenser such as an A-Frame that dispenses products into cartons as they move along a conveyor

- Person-to-goods system that utilizes an autonomous mobile robot (AMR) directed to an active pick location to await order picker activity

- Goods-to-person system where a robot autonomously picks an item and brings it to a stationary operator at a workstation

When considering micro-fulfillment center automation, it is crucial to consider the facility and operational parameters. These parameters include the number of orders per day, lines or units per order, unique SKU quantity to be stored, service level agreements (e.g., 2-day shipping), product unit of measure (shipped in eaches, cases, pallets), and product type (e.g., hazmat, fragile, kitting needed, etc.).

Below are some broad generalizations for which technologies to implement for which micro-fulfillment strategies. Of course, each business case is different and requires a detailed analysis to ensure that the solution will benefit your operation.

| Micro-Fulfillment Strategy | Requirements | Technology |

| Online Center | Large volume High level of order batching | Exotec Conveyance BG robotic packing into polybags or boxes |

| Dark Store | Small to medium-sized footprint Low-bay storage Dense storage | Caja A-frame |

| In-Store | Small footprint Fast and non-invasive implementation Dense storage | Caja BG robotic packing into bags |

Who Can Benefit from a Micro-Fulfillment Strategy?

The micro-fulfillment strategy works best for sectors that have relatively small, high-turnover items.

Grocery retailers have already implemented micro-fulfillment strategies as a way to keep up with online grocery orders during the COVID-19 pandemic. Micro-fulfillment methods work for grocery retailers because the perishable items have a high turnover, and the stores generally know which items have the highest turnover.

Retailers and eCommerce companies selling products that fluctuate in demand can also benefit from micro-fulfillment. During peak season, demand for holiday gifts like candles, phones, and sweaters can drastically increase and then drastically decrease after peak season.

Automated micro-fulfillment centers are more flexible to demand changes since they are not as big and robust as traditional fulfillment centers.

Is Micro-Fulfillment Right for You?

The answer is it depends. There are so many parameters that must be considered, as mentioned previously, so it is wise to partner with a systems integration expert.

A systems integrator specializes in sourcing the appropriate automation and robotic technology to maximize the throughput, efficiency, and ROI. An integrator, like Hy-Tek, ensures the individual technologies work cohesively together, so there is no guesswork.