Insights from Joe McGrath, Systems Development Lead, and Mitch Hoogland, Business Development Manager-Automation at CASI.

The Automation Insider host Joe McGrath was joined by Mitch Hoogland, Business Development Manager-Automation at CASI, to discuss the benefits of automating inbound box opening and decanting. As automation in other areas of the warehouse increases, the interest in automating inbound processes like unboxing has intensified.

Decanting Defined

Many people use “decanting” and “opening boxes” interchangeably to describe how a warehouse gets product from a truck and into the warehouse system as quickly and efficiently as possible. It’s a process that can be human-operated, fully automated, or a combination of the two.

The idea of box opening may seem simplistic, but in many industries, such as food and beverage or apparel, the number of boxes to be processed is immense. While there are many ways in which a box can be opened and the product moved downstream, the goal is to efficiently move the product without damaging the item or causing injury.

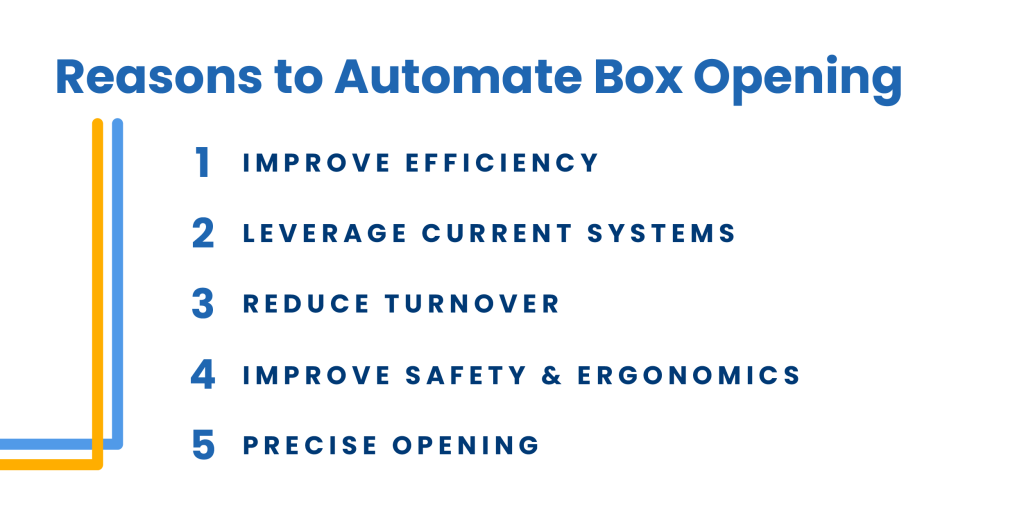

Reasons to Automate Box Opening

Many organizations have invested in high-end automated storage and retrieval systems (ASRS) and autonomous mobile robots (AMR) that have advanced upstream and downstream processes. The success of automation in these spaces often encourages organizations to look at how automation can improve the inbound space, Hoogland explains.

- Improve efficiency. The sheer volume of boxes can lead to a backlog of material waiting to be processed. This delays the product getting out the door and to the customer.

“If you can’t fill bins fast enough because of a backlog of products ready to [be] opened, then it’s time to automate,” says Hoogland.

- Leverage current systems. Current investments in robotics systems, such as AMR or ASRS, or warehouse management systems can be better leveraged by automating the inbound process.

- Reduce turnover. Unboxing puts a physical strain on workers. “It’s a high turnover area. It’s a brutal job,” adds Hoogland. Reducing the repetitive actions with partial automation or automating the entire process can elevate this pain point.

- Improve safety and ergonomics. The use of knives or other tools to open boxes is a varied process from warehouse to warehouse. Even though some organizations restrict the type of tools that can be used to unbox, injuries occur especially when dealing with a large volume. Worker morale suffers when there is injury, and there is a high financial cost as well.

“We’ve seen it cost an organization anywhere from $30-$40,000 per major injury,” says Hoogland. “If you’ve had a couple of major injuries this year, which most companies that are opening a lot of boxes have, then there’s a better way to do it. Maybe it’s time to start thinking [about] automating.”

The physical act of opening thousands of boxes a day or lifting and decanting, for example, 40lbs of raw material, can impact worker safety and ergonomics. Automation that uses AMR or box cutting robotics can greatly reduce the strain on workers.

- Precise opening. Workers opening boxes may have to be very careful opening certain boxes so as to not damage the products inside, and robotics can deliver precision opening without slowing down the process.

Time to Automate

Many 3PL companies are exploring automating box cutting, especially as the capabilities of unboxing robotics can accommodate different cuts and industry needs. The way in which these robotics are utilized is dependent upon the dimensions of the boxes received – and the downstream process. For example, the cut or decanting process would be different if the product is to be put away onto racks for future picking or if the product is put onto ASRS.

As Hoogland explains, receiving “the same box over and over, automating that, of course, is a lot easier because there are a lot fewer variables.” A vendor with consistent box dimensions can make automating the unboxing process easy.

But that doesn’t mean that CASI isn’t up for the challenge, as Hoogland explains, the CASI system is often up and running the same day it’s installed, and the CASI engineers “love a challenge” when it comes to addressing their client’s needs.

🎧 Take a deeper look into decanting and how CASI is changing inbound receiving and efficiency with the full episode of The Automation Insider.

Want to explore your options? Contact Hy-Tek Intralogistics to discover how our warehouse software experts can help you build a system tailored to your future.