Insights by Ray DeMelfi and Lori Gibson

Billions of dollars are being poured into warehouse automation, and for good reason. With rising labor costs, tighter SLAs, and increasing demand volatility, automation can offer real performance gains. But despite the impressive capabilities of today’s systems, many projects underdeliver. The problem usually isn’t the technology. It’s how the company prepares for it.

Operational readiness is the difference between hitting your KPIs or scrambling to contain chaos during and following project go-live. It’s not just about plugging in equipment or connecting software. It’s about making sure your people, processes, and data are ready to support and sustain change.

In this blog, we’ll break down what operational readiness really involves, why it often gets overlooked, and how to build a practical, proactive plan to support your automation goals from day one.

What Is Operational Readiness in Automation?

Operational readiness refers to the process of preparing your organization, people, processes, and systems to adopt, absorb, and scale an automation solution. It’s the connection between strategy and execution.

Unlike technical readiness, which focuses on getting hardware installed or software configured, operational readiness ensures that the day-to-day operation can actually function in the new environment. It’s about aligning workflows, updating standard operating procedures (SOPs), training employees, validating data, and running test scenarios that reflect real warehouse conditions.

When done well, these efforts reduce friction, improve adoption, and help ensure that automation investments generate ROI sooner and more reliably.

Why Operational Readiness is Often Overlooked

Despite its importance, operational readiness is one of the most overlooked phases of an automation project. Here’s why:

Over-focus on technology

It’s easy to get caught up in system specs, speeds, and integration maps. While those elements matter, they don’t guarantee successful operation if the people running the facility aren’t prepared for how their roles will change.

Mistaking integration for readiness

Just because systems are connected doesn’t mean they’re aligned. For example, a warehouse management system (WMS) may communicate with a robotic system, but if the workflows, inventory practices, or exception processes don’t match the new logic, breakdowns occur quickly.

Lack of ownership

Many teams don’t assign a clear owner for operational readiness. It’s not simply a task for the engineering team, nor does it fall solely to operations. Without a cross-functional leader or task force, it often slips through the cracks.

Time and go-live pressures

As timelines get tighter near deployment, operational readiness is one of the first things to get cut. The assumption is that any gaps can be fixed post go-live, but by then, costs are higher and confidence is lower.

Real-World Consequences of Poor Operational Readiness

When operational readiness is an afterthought, the consequences show up fast:

Delayed ROI

If teams aren’t ready, the benefits of automation take longer to materialize. You end up paying for both the system and the overtime needed to patch over avoidable issues.

Change resistance

Employees who don’t understand the “why” behind changes or who aren’t trained to navigate new systems tend to resist them. That resistance often spreads, leading to disengagement and turnover.

Manual workarounds

When teams aren’t fully prepared, they default to what they know. Without clear SOPs, role-based training, or contingency plans, manual workarounds creep in. These shortcuts slow operations and undermine the system’s value.

Often, the issue isn’t with the automation itself but with how it’s being used. In some facilities, automation sits underutilized because teams weren’t informed on which SKUs to run through the system. If product slotting doesn’t align with system capabilities, or if operators aren’t confident navigating exceptions, automation can become a bottleneck rather than an advantage.

These gaps create inefficiencies, introduce risk, and delay the return on investment. Worse, they can shake confidence in the solution, even when the root cause is operational, not technical.

Customer impact

During a chaotic go-live, service levels can drop. Shipments are delayed. Errors increase. Customers notice. And once trust erodes, it’s hard to rebuild.

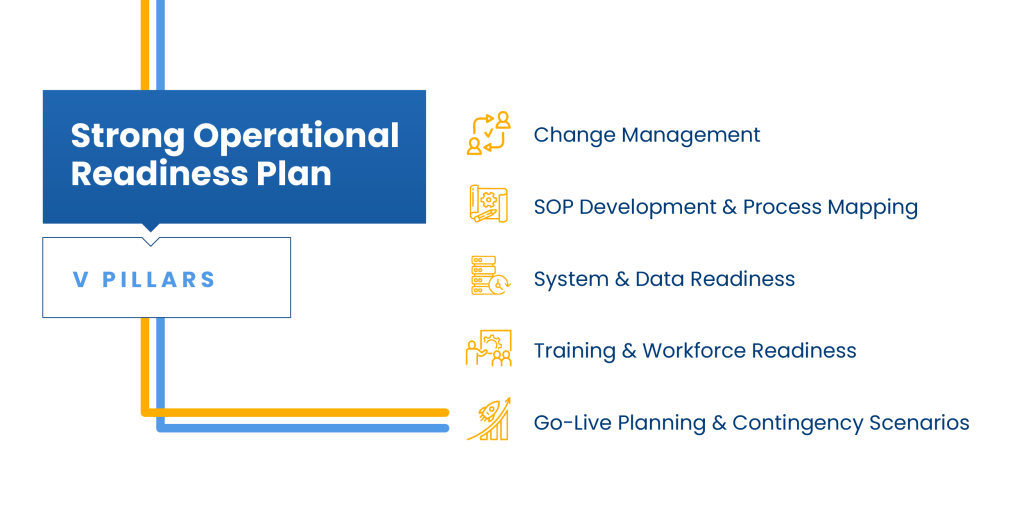

Key Pillars of a Strong Operational Readiness Plan

A well-structured operational readiness plan spans five core areas. Each plays a critical role in ensuring that your automation system works as intended from day one.

Change Management: Operational change starts with people. Change management ensures that your team is not just aware of what’s coming but engaged in the process.

- Align leadership across departments early

- Communicate proactively about the impact of changes

- Identify “change champions” on the floor who can reinforce new behaviors

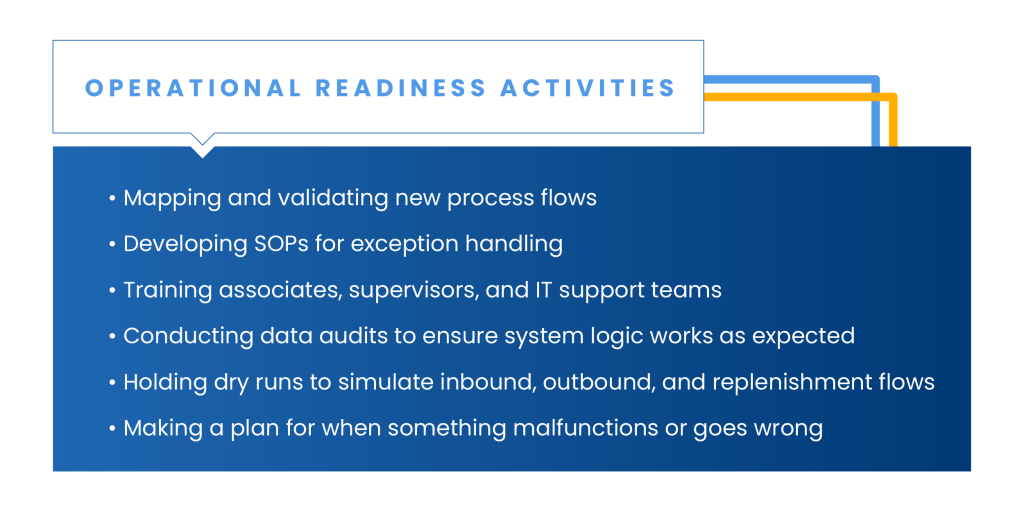

SOP Development and Process Mapping: Automation reshapes how tasks are performed and how exceptions are handled.

- Map future-state workflows with input from both system designers and operators

- Review and validate edge cases such as incorrect picks, no-reads, or damaged goods

- Document updated SOPs in clear, accessible formats

System and Data Readiness: Your automation is only as smart as the data it’s fed.

- Audit master data for accuracy and consistency

- Test system logic in end-to-end scenarios before go-live

- Ensure your WMS or warehouse execution system (WES) aligns with physical flow and process rules

Training and Workforce Readiness: Even the best system won’t perform if your team isn’t ready to run it.

- Provide role-specific training well before launch

- Use job aids, simulations, and practice shifts to reinforce learning

- Ensure supervisors are confident in their ability to lead in the new environment

Go-Live Planning and Contingency Scenarios: Treat go-live like a mission-critical launch.

- Define escalation paths for issues during startup

- Set up a support “war room” with real-time assistance from IT, engineering, and operations

- Establish backup plans in case of system disruptions

- Post-go-live process adherence reviews to retrain associates, and/or realign procedures as needed

Operational Readiness Self-Check

Before moving to deployment, ask your team these questions:

- Have your SOPs been updated to reflect post-automation workflows?

- Have you planned for testing of end-to-end scenarios, including edge cases and disruptions?

- Are operators, supervisors, and leadership aligned on what changes are coming and why?

If the answer is “no” to more than one, your team may face a costly and avoidable stabilization period after go-live. These are the kinds of gaps that can derail even the best-designed systems.

Use our operational readiness self-check list to guide internal discussions and identify areas that need attention before go-live.

Download the checklist to get started.

Building Operational Readiness into Your Automation Timeline

Operational readiness should be treated as a dedicated project phase and thought about and planned for from a project’s iteration. It is not simply a task to complete at the end.

Begin readiness planning as early as the design stage. Bring in stakeholders from operations, IT, HR, and warehouse leadership to form a cross-functional task force. Set milestones for SOP drafts, training completion, and mock go-live activities. This approach helps identify risks early and builds confidence across teams.

By making readiness part of the overall timeline, you reduce surprises and avoid last-minute pressure that can derail go-live.

Final Thought: Don’t Just Launch. Prepare to Perform.

The best automation systems still require humans to run them effectively. Operational readiness bridges the gap between technology and execution. It ensures your investment delivers on its promise from the first day.

Think beyond deployment. Focus on adoption, performance, and long-term sustainability.

Let’s Talk Operational Readiness Planning

Operational readiness is where successful automation begins. It is also where many projects stumble. Whether you’re preparing for your first deployment or scaling a mature system, our team is ready to help.