Insights from Derek Miller, Senior Account Executive

When the Seasons Change, So Does the Demand

As the weather warms up, coolers come out. Neighborhoods fill with the sounds of cookouts, pool parties, and weekend gatherings. As summer days cool down into fall evenings, football season arrives, bringing packed stadiums and watch parties. Before long, the holidays take over with family meals, office parties, and end-of-year celebrations.

Across all these moments, one thing remains constant: people want their favorite beverages available and in stock. As customer preferences become more specified, craft beverages of all types continue to multiply, increasing an already substantial SKU base for distributors, at a time when labor is more scarce and costly than ever before. That demand puts serious pressure on beverage distribution operations. These demands can be answered with robotic automation. With the ability to increase throughput, improve accuracy, and reduce dependence on manual labor, robotic systems are becoming essential tools for operations leaders looking to stay ahead during peak season.

The Pressures of Peak Season in Distribution

Peak season is a familiar challenge in distribution, bringing sharp increases in volume, SKU complexity, and delivery expectations. While the timing may vary by industry or region, the operational impact is universal. Facilities face rising order counts, tighter fulfillment windows, and higher customer expectations, all while trying to maintain accuracy and efficiency.

For further learning on peak season readiness, register for our upcoming webinar with Supply Chain Brain.

The sudden nature of these spikes puts intense pressure on existing resources. Inventory turns faster. Order profiles shift. Labor requirements climb. Many operations respond by bringing in temporary staff, running overtime shifts, or pushing existing teams to work faster. These stopgap measures often lead to burnout, mistakes, and inefficiencies that can ripple across the supply chain.

“Hiring seasonal staff to manage peak periods has long been standard practice but with the logistics sector expecting to face worker shortages of 400,000 by 2026, this is becoming increasingly difficult and unsustainable.” –Robotics Tomorrow

Modern distribution strategies increasingly recognize that manual processes are not designed to scale with this kind of variability. As a result, more organizations are investing in flexible solutions that can adapt to volume surges without sacrificing speed or accuracy. This includes technology that improves throughput, increases picking precision, and supports real-time visibility across the facility.

The Impact of High-Demand Seasons on Beverage Distribution

Busy seasons affect every aspect of beverage distribution. Distributors must be ready to respond quickly, without sacrificing accuracy or increasing costs. Key challenges include:

- Increased SKU variety: Limited-time offerings and seasonal packaging make inventory more complex to manage and pick.

- High-volume orders: Retailers, convenience stores, venues, and direct-to-consumer channels all place larger and more frequent orders.

- Tighter fulfillment windows: Delays are not just inconvenient. They can lead to lost shelf space or strained customer relationships.

- Labor shortages: Many warehouses struggle to scale their workforce fast enough to keep up with demand spikes.

How Robotic Automation Solves Seasonal Distribution Challenges

Faster Fulfillment Without Additional Headcount

Autonomous mobile robots (AMRs), automated storage and retrieval systems (AS/RS), and robotic case handling systems work consistently at high speeds. They allow distribution centers to scale up operations during peak times without the need to hire, train, and manage temporary workers.

These systems increase operational abilities, greatly improving processing efficiency, especially for the ever-growing SKU tail. By taking over repetitive tasks such as transporting goods or sorting cartons, robotic systems increase throughput and reduce dependency on fluctuating labor availability.

Flexibility to Handle SKU Complexity

Robotic automation offers the adaptability needed to keep up with the constant shifts in packaging formats and SKU variety that beverage distributors face. Systems designed for full-case picking, mixed-case palletizing, and depalletizing can accommodate everything from slim cans and glass bottles to shrink-wrapped bundles and specialty cartons.

This flexibility is especially valuable during peak seasons, when promotional packs, limited-run SKUs, and high-turnover products enter the mix. Automated systems can be programmed to recognize and adjust to different case sizes, stacking patterns, and load requirements, without disrupting throughput.

Rather than requiring operators to relearn handling protocols for every new item, robotic systems maintain consistent performance and reduce the margin for error. The result is a smoother operation that can keep up with changing demand, packaging updates, and SKU introductions, all while maintaining speed and accuracy.

Smarter Use of Space

Robotic systems are designed to make better use of every square foot in your warehouse. High-density storage solutions combined with goods-to-person picking/buffering models allow for more inventory to be stored closer to where it is needed. These systems reduce or even eliminate dependency on space-consuming conveyor sortation systems while decreasing travel times for operators.

Facilities that install these systems often delay or avoid the need for expansion because of the improved space utilization.

Real-Time Visibility and Adaptability

When robotics are integrated with warehouse execution software (WES), operations leaders gain access to real-time data and control. During high-demand periods, this visibility makes it easier to prioritize fast-moving SKUs, reallocate resources, and eliminate bottlenecks before they affect service.

Decisions can be based on actual performance data rather than estimates or guesswork.

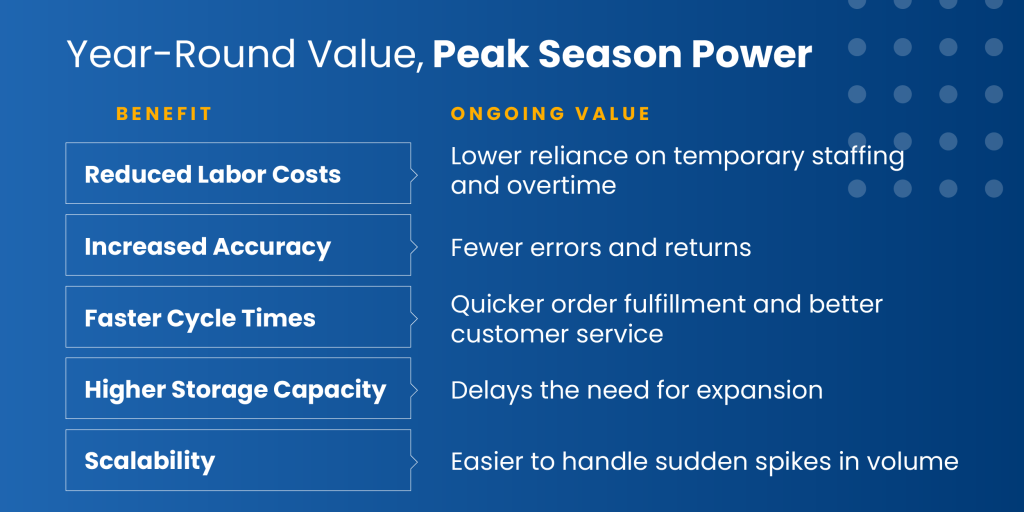

Year-Round Value, Peak Season Power

While automation shines during high-demand seasons, the benefits continue all year. Key advantages include:

Why the Right Automation Partner Matters

Choosing the right automation partner is just as critical as selecting the right technology. At Hy-Tek Intralogistics, we offer end-to-end solutions that combine advanced robotics, warehouse software, and expert systems integration, backed by decades of experience in high-volume beverage distribution environments.

Beverage operations have unique challenges, from heavy-case handling to SKU variety and seasonal demand spikes. Hy-Tek understands these complexities and designs solutions that are not only tailored to today’s needs but are also built to scale as your business grows.

When evaluating automation partners, look for a team that:

- Provides complete solutions, including WES software, robotics, and system integration.

- Knows the beverage industry and its distribution challenges.

- Works with your team to find the right technology and solution for your operations, not simply a cookie-cutter solution.

- Designs systems with scalability and flexibility in mind.

- Offers long-term support, training, and maintenance to keep your operation running at peak performance.

With Hy-Tek, you gain more than a vendor. You gain a strategic partner who helps you avoid costly missteps, adapt quickly to changing demand, and future-proof your facility for peak seasons and beyond.

Get Ahead of the Next Busy Season

Whether your peak is driven by summer heat, fall tailgates, or holiday cheer, one thing is clear: high-demand seasons will continue to test the limits of your distribution operation.

Now is the time to prepare. Ask yourself:

- Can my current systems handle a 25 percent increase in orders without compromising accuracy?

- How quickly can I respond to shifts in customer demand?

- What would happen if I could not hire the temporary workers I usually rely on?

If these questions raise concerns, it might be time to explore how robotic automation can help. Investing in the right technology now can give you the flexibility and confidence to perform at your best when demand is at its highest.

Final Thoughts

Beverage distribution is a seasonal business, but the expectations from customers and retailers are constant. Whether it is the rush of summer or the crunch of the holiday season, robotic automation provides the speed, consistency, and adaptability modern warehouses need to stay competitive.

Instead of scrambling to meet the next wave of demand, put systems in place that help you lead it.

Ready to optimize your beverage distribution operation?

Connect with the automation experts at Hy-Tek Intralogistics. We help beverage distributors and bottlers implement smart robotic solutions that improve performance during high-demand seasons and beyond.