Insights from Zac Boehm, Chief Automation Officer

The Future of Beverage Distribution: Leveraging Automation for Efficiency

The beverage industry is surging, with the non-alcoholic sector projected to exceed $280 billion in 2025 and the spirits market, both in-home and out-of-home, valued at approximately $387 billion (per Statista).

With both segments growing at a CAGR above 4%, beverage distributors face mounting pressure to scale quickly, adapt to SKU proliferation, and keep up with ever-evolving consumer preferences. The pressure is on to optimize operations, reduce costs, and streamline fulfillment, making automation and data-driven technologies no longer a luxury but a necessity.

Is your operation ready to scale efficiently and make the leap into automation?

Beverage Distribution Channels

Whether grabbing a cold beer from the fridge, ordering your favorite soda at a restaurant, or picking up a case of sparkling water at the grocery store, there is an intricate distribution network behind the scenes to make it happen. Every beverage travels through a carefully coordinated supply chain, from production to retail shelves, and finally reaches the end consumer, you.

Understanding these key distribution channels helps highlight where automation can create efficiencies and improve operations.

- Producers: These are the manufacturers responsible for crafting beverages and managing the initial stages of logistics.

- Distributors: Independent businesses that help brands bring their products to market, overseeing warehousing, transportation, and inventory management.

- Retailers: Businesses that sell beverages directly to consumers, including grocery stores, gas stations, restaurants, and online platforms.

Key Disruptors in Beverage Distribution

The beverage industry faces a growing set of challenges that impact efficiency, profitability, and overall operations. To remain competitive, beverage distributors must anticipate and adapt to these disruptors by leveraging automation, data-driven decision-making, and strategic supply chain optimization.

Six of the most pressing challenges in the beverage supply chain include:

- Distribution Costs: Rising fuel and labor costs impact profitability.

- Inventory Management: Optimizing stock levels to minimize waste while meeting demand.

- Returns Processing: Increased complexity due to shifting retail requirements.

- Seasonality: Fluctuating consumer demand throughout the year.

- SKU Variability: Growing product assortments require adaptable logistics.

- Omni-Channel Fulfillment: The push toward e-commerce and direct-to-consumer sales is transforming beverage distribution models.

How to Start Leveraging Technology

For beverage distributors, implementing automation is not just about adding robots or software, it starts with a deep understanding of your current operations. Before making any investments, it is essential to create a clear foundation for identifying automation-ready opportunities. A structured, well-thought-out approach ensures that automation gets implemented where it delivers the most value, improving speed, accuracy, and efficiency.

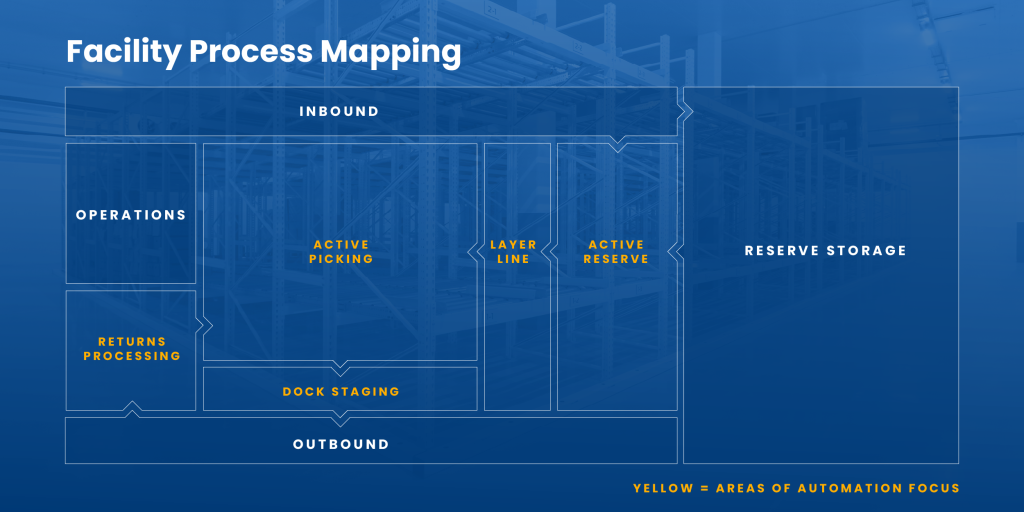

- Map Out Process Requirements

- Mapping out process requirements involves assessing each stage of your operations, from receiving to shipping, to identify inefficiencies and bottlenecks. By documenting workflows and recognizing manual tasks, you can pinpoint areas where automation can have the greatest impact on improving speed, accuracy, and overall productivity.

- Analyze Data Trends

- Analyzing data trends is critical for making informed automation decisions, as reliable data helps identify key patterns that can drive operational improvements. These trends not only reveal areas of inefficiency but also help determine the most effective automation solutions to optimize throughput, reduce waste, and improve overall supply chain performance.

- By examining factors such as SKU velocity, packaging types, palletization strategies, and seasonal demand shifts, distributors can gain valuable insight into their inventory and workflow dynamics.

- Adapt to SKU Growth

- To adapt to SKU growth, it is essential to ensure that storage and retrieval systems can handle SKU proliferation, with data insights guiding technology choices such as storage methods, replenishment processes, and slotting logic, while considering factors like SKU variability and velocity slotting.

- Prioritize Scalability

- To prioritize scalability, it is important to work with an experienced automation partner, like Hy-Tek, to design flexible solutions that can grow with your business. This means selecting systems that not only meet current needs but also can adapt as demand increases, new products are introduced, and operational requirements evolve. By planning for future growth and leveraging scalable technology, distributors can ensure their operations remain efficient, agile, and cost-effective as they scale.

Areas of Automation Focus for Beverage Distribution

To maximize efficiency, beverage distributors can leverage automation in these key areas:

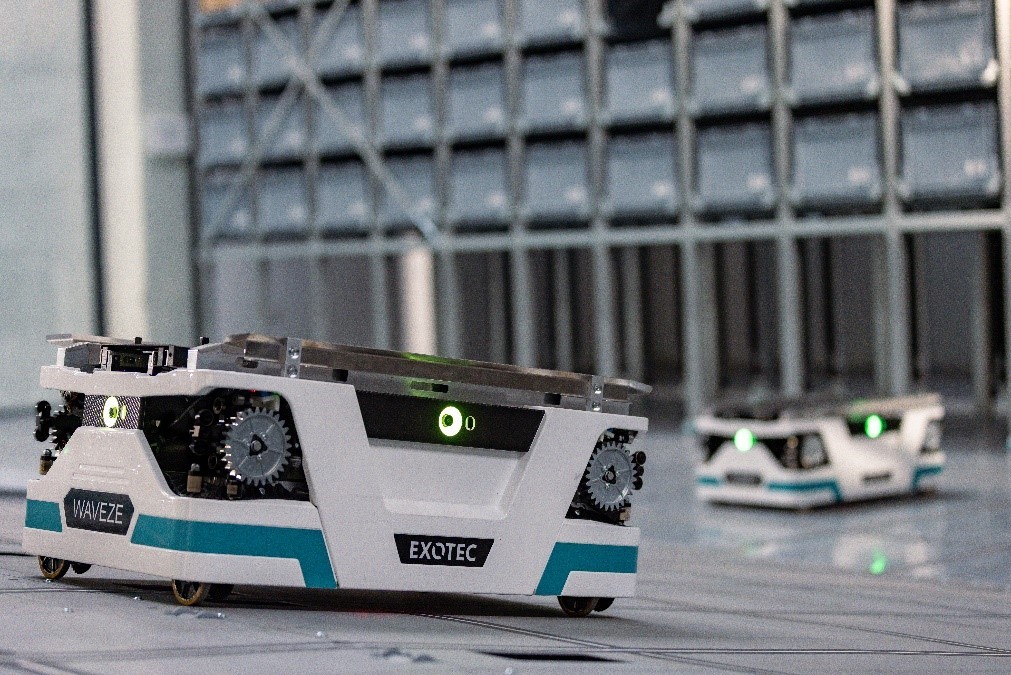

Automated Storage and Retrieval Systems (ASRS)

- Enables dense pallet storage, maximizing warehouse space.

- Facilitates just-in-time fulfillment, aligning stock levels with demand.

- It supports multi-functional storage and handles diverse inventory types efficiently.

📊 To learn more about AS/RS solutions for the beverage industry, read this article by Supply Chain Dive about our robotic partner, Exotec, and a beverage solution that Hy-Tek solutioned and integrated for one of the largest beer distributors in the United States.

Robotic Depalletizing for Picking and Replenishment

- Increases speed and efficiency, reducing labor dependency.

- Enhances safety, minimizing injuries from manual lifting.

- Improves accuracy, using vision systems to reduce errors.

- Lowers costs, decreasing reliance on manual labor.

📊For further learning on robotic depalletization, check out our podcast, The Automation Insider, featuring AWL.

Goods-to-Person (GTP) Systems for Active Picking

- Supports flexible storage slotting, adapting to seasonal SKU changes.

- Scales with demand, optimizing warehouse capacity.

- Facilitates sequence-based outbound processing, ensuring accuracy in order fulfillment.

Automated Palletizing, Wrapping, and Labeling

- Boosts manual palletizing efficiency by up to 500%.

- Ensures consistent stretch wrapping, improving shipment security.

- Enhances labeling accuracy, streamlining tracking and verification.

The Role of Software in Optimization

As beverage distribution becomes increasingly reliant on technology, cybersecurity has emerged as a critical concern. According to a recent study, cyber risks were shown to have the largest impact on supply chains, rated by 84% of participants as high or medium impact. Protecting data and operational integrity is essential as digital transformation accelerates.

Warehouse execution software (WES) plays a critical role in optimizing beverage distribution operations while also incorporating cybersecurity measures to safeguard data and systems. Advanced WES solutions enable:

- Real-time inventory tracking, minimizing stockouts and overstock.

- Dynamic slotting and replenishment, improving space utilization.

- Data-driven decision-making, leveraging analytics for process improvements.

At Hy-Tek, our IntraOne software platform integrates seamlessly with your existing ERP and warehouse operations, providing end-to-end visibility, robust security protocols, and intelligent automation that drive efficiency, reduce risk, and accelerate your digital transformation.

Learn more about how IntraOne can streamline your distribution operations and protect your data integrity.

Next Steps: Future-Proofing Your Beverage Distribution

To successfully integrate automation, beverage distributors should:

- Find the right technology partner – Here at Hy-Tek, we partner with a wide variety of industry-leading OEMs and help you find the right fit(s) for your facility.

- Evaluate and map current processes.

- Ensure data readiness – Validate date and identify gaps.

- Prioritize operational readiness and change management – Train staff and refine processes for smooth implementation.

- Prepare for scalability – Build a flexible automation strategy to accommodate future growth.

Brewing Up Solutions

The beverage industry is at a tipping point where the adoption of automation and technology is no longer optional, it is the engine for growth and stability in distribution. By leveraging automation and software-driven optimization, distributors can enhance efficiency, reduce costs, and meet the evolving demands of the market.

To learn more about how Hy-Tek Intralogistics can help transform your beverage distribution operations, schedule a discovery call with one of our experts today!