Warehouse automation in the supply chain is a huge topic of discussion, and with the introduction of robotics, companies are able to see larger returns and faster payback periods than traditional material handling automation and equipment.

Additionally, the cost has decreased significantly as the technology is more prevalent. This has made them more accessible to companies who may have previously been priced out of the market.

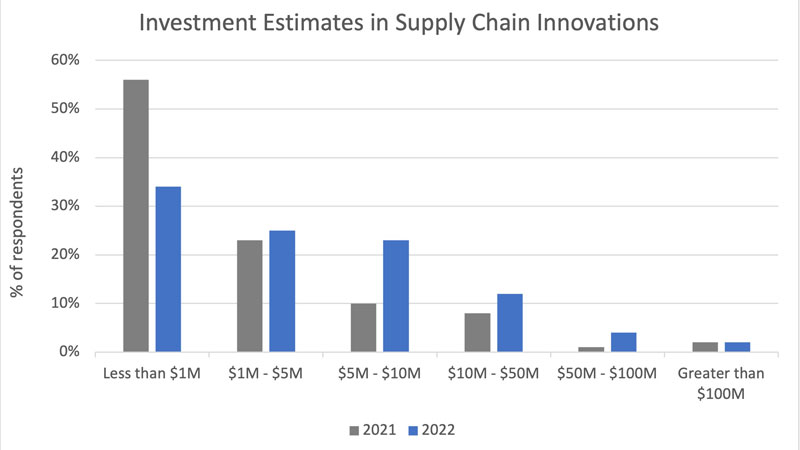

Based off of MHI’s Annual Industry Report, more businesses are shifting from innovation investments that cost under $1M to investments that cost between $5M and $50M to further automate their supply chain.

When thinking about implementing robotics into your supply chain, calculating the expected Return on Investment (ROI) as well as analyzing the investment’s payback period plays a large role in whether the investment should be pursued.

In this post we will cover:

- What is ROI?

- Types of Savings

- Types of Expenses

- What is a typical ROI Timeframe?

- Top 3 Robots with Highest ROI

- What Industries Should Invest?

What is ROI?

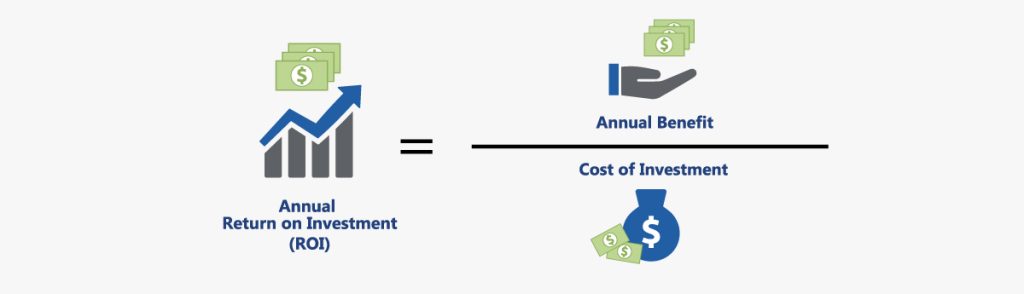

Return on investment is a performance measurement ratio between annual benefit and the cost of the investment – the higher the percentage, the higher the return and more attractive the investment.

This ratio will answer the question, “What percent (%) annual return do I get on my investment?”

ROI = Annual net benefit (revenue + savings – expenses) / initial investment expense

For example, you have an initial cost of $1,000,000. Each year you have a $300,000 increase in revenue (due to the investment), annual savings of $50,000, and annual expenses of $100,000. In this project, the annual net benefit is $250,000 ($300,000 + $50,000 -$100,000). Divide $250,000 by $1,000,000 to give you 25% annual return on investment for your project. In this example, the payback period would be 4 years (1 divided by 25%).

Now that we know how to calculate ROI for your warehouse, let’s compare the savings to the expenses.

Types of Savings

ROI = Annual net benefit (revenue + savings – expenses) / initial investment expense

A higher return on investment is achieved by reducing costs as much as possible. There are many ways to reduce spending through robotics, with labor being the easiest to quantify at the time of investment.

When integrating multimillion-dollar, robotic investments, the savings incurred extend into the following areas:

- Reduced labor costs. Robots performing non-value-added movement operations, such as transporting an empty pallet across the building, reduces labor costs.

- Lower turnover rates. According to Employee Benefit News, employers spend an average of 33% of a worker’s annual salary to replace just one employee. For an employee that makes $45,000 per year, it would cost $15,000 to replace them. With turnover rates being an all-time high, the savings incurred through robotic implementation is astronomical.

- Higher productivity. Robotic systems can typically outperform mundane tasks faster than humans, resulting in an increased process efficiency and productivity.

- Space savings. Robotics don’t have to adhere to capacity limitations or minimum walkway widths that may be outlined by OSHA guidelines. Therefore, the storage can be denser and space can be used more efficiently.

- Reduced safety infractions. A robot experiences fewer safety incidents than a human, meaning fewer repairs to surrounding equipment and infrastructure. For example, there would be fewer instances of manually-operated forklifts running into walls which then need repaired. In addition, fewer safety infractions can positively affect a company’s Experience Modification Rating (EMR) which then reduces workers’ compensation rates through insurance providers.

- Cost avoidance. Cost avoidance consists of any actions that avoid spending money in the future. This includes things like investing in process improvement or robotic technology that reduces the need for additional employees.

One important factor that is hard to quantify is that of customer satisfaction.

The benefits and savings outlined above can be shown against the bottom line, however, the ultimate and most important factor is that these savings and process optimizations mean fewer unsatisfied customers due to late or inaccurate orders. With the market being so saturated with online retailers, customers are quick to switch brands if one does not meet their expectations.

Types of Expenses

ROI = Annual net benefit (revenue + savings – expenses) / initial investment expense

Any business that is integrating robotics into their warehouse should be aware of the additional expenses that will be incurred.

- Setup costs. The time and effort that goes into configuration, setup, and deployment.

- Maintenance expenses. Maintenance costs include the cost of repairing and maintaining the robots, as well as the cost of any necessary software updates.

- Consumable expenses. Consumable costs include the cost of replacement parts and materials, such as batteries and lubricants.

- Increased electricity usage. Robotics will increase a company’s electricity usage as the robots will be running for longer periods of time.

- Training. With any new system, employee training is required which requires both time and money.

Although these additional costs may seem daunting, they should be considered in light of the potential productivity gains that can be achieved with robotic automation.

What is a Typical ROI Timeframe?

It depends. On average, people can expect to see a return on the robotic investment within 3 to 5 years.

In a few instances, customers are not even considering the ROI or the payback period, but they are saying, “If I don’t invest in automation, and if I can’t keep up with consumer demand, I will lose customers and lose market share.”

The choice to invest in robotics is multi-faceted, where industry competitiveness and market share are not as obvious as the dollar return but play a significant role in the decision-making process.

Top 3 Robots with the Highest ROI

There are endless types of robotics that can help you achieve maximum savings and a greater return. Below, we outline the main processes and technologies to consider for warehouse automation that will experience the most savings and a higher ROI.

1. Autonomous Mobile Robots

For companies that are just beginning to consider robotics that may not be interested in such significant capital investments, autonomous mobile robots (AMR) are relatively quick and easy to implement into existing operations.

AMRs for material handling help automate pallet and inventory movement, thus reducing labor and making it a more efficient facility. They move independently, so there is a significant decrease in the number of associates needed for this non-value-added task. AMRs allow employees to focus on and complete more value-added tasks while creating a safer work environment.

| w/o AMRs (Current) | w/ AMRs | +/- Yearly Change | |

|---|---|---|---|

| Pallet Rate (Per Hour) | 50 Pallets PH | 50 Pallets PH | |

| Team Members | 6 Associates | 2 Associates | (-4) Associates |

| Equipment Savings | 20,000 | – | (-) $75,000 |

| Turnover Costs | $10k per associate per year | $10k per associate per year | (-) $40,000 |

| Safety | $20,000 | – | (-) $40,000 |

With AMRs, the movement of pallets is not necessarily faster, as shown in the row labeled, “Pallet Rate” in the table above. In this example, both the associate and robot can move 50 pallets per hour. However, in the row labeled, “Team Members,” you see that you only need 2 associates operating in conjunction with the AMRs versus the six associates without AMRs.

2. Person-to-Goods Robots

In a Person-to-Goods (P2G) system, the robotic technology guides pickers to locations during a pick process, making non-value-added movement more efficient. Like Mobile Robotics, a Person-to-Goods system allows for your employees to focus on more value-added tasks, as well as making the picking process more accurate.

| w/o P2G Solution (Current) | w/ P2G Solution | +/- Yearly Change | |

|---|---|---|---|

| Pick Rate (Units Per Hour) | 50 UPH | 200 UPH | (+) 150 UPH |

| Pickers Required | 100 Pickers | 25 Pickers | (-) 75 Pickers |

| Cost Avoidance | – | – | – |

| Turnover Costs | $10k per person per year | $10k per person per year | (-) $75,000 |

| Safety | – | – | – |

| Space Savings | – | – | – |

| Accuracy | 90% | 98% | (+) 8% |

The table depicts even more significant savings than Mobile Robotics. In this example, the pick rate drastically increases by 300%, and the number of required associates for walking to pick locations drastically decreases by 75%. Therefore, you can pick more orders with fewer labor hours.

3. Goods-to-Person Robots

In a Goods-to-Person (G2P) system, the robotic technology drives products to stationary pickers to eliminate non-value-added movement. In a Goods-to-Person system, your pick rate savings are maximized since labor is reduced even more than in the Person-to-Goods methodology. Space savings can be significant since more SKUs can be stored closer together, and order accuracy is increased, allowing for more cost savings in the future.

| w/o G2P (Current) | w/ G2P | +/- Yearly Change | |

|---|---|---|---|

| Pick Rate (Units Per Hour) | 50 UPH | 400 UPH | (+) 350 UPH |

| Pickers Required | 100 Pickers | 13 Pickers | (-) 75 Pickers |

| Cost Avoidance | – | – | – |

| Turnover Costs | $10k per person per year | $10k per person per year | (-) $870,000 |

| Safety | – | – | – |

| Space Savings | 50,000 sqft | 25,000 sqft | (-) 25,000 sqft |

| Accuracy | 90% | 98% | (+) 8% |

In this example, the units per hour (UPH) picked increases by 700%, and the pickers required to walk to pick locations decrease by 87%. Goods-to-Person robotic technology offers the largest ROI when discussing picking technology.

Comparing the Top 3 Types of Robotics

| Autonomous Mobile Robot | Person to Goods | Goods to Person | |

|---|---|---|---|

| Automation level | Low – Medium | Low – Medium | Medium – High |

| Savings | Medium | Medium – High | High |

| Scalability | High | High | High |

| Upfront Costs | Low – Medium | Low – Medium | High |

| Annual Return on Investment | Medium | Low – Medium | High |

How to Increase ROI

1. Automate operations that utilize large amounts of non-value-added tasks

Automating the picking operations for order fulfillment typically experiences the highest ROI and shortest payback period within eCommerce and fulfillment processes. AHS has implemented robotic picking solutions, such as Caja and Exotec, that boost the pick speed by 10x which means the company can typically see a return within 2-3 years.

2. Choose a scalable robotic technology

When automating your warehouse, flexible and scalable robotic solutions are the key to achieving the highest return on investment. Flexibility and scalability act as risk mitigators to improper and incorrect demand forecasting.

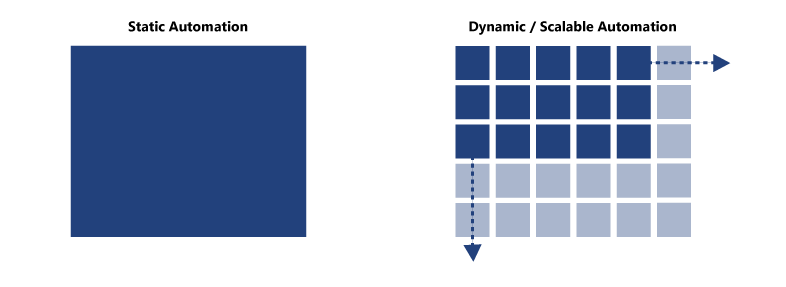

Fulfillment and distribution companies have been implementing automation solutions, including sortation and conveyance, for decades. These solutions can be categorized as “static automation” since they are calibrated to meet the demand for a five or ten-year projection.

What’s the problem with static automation? If projections are incorrect, and the company meets those projections three years from now (versus 10 years from now), the solution will not be able to meet the desired output in ten years.

Robotics can be classified as “dynamic automation,” meaning they are scalable and flexible systems that do not necessarily have to be calibrated for a five or ten-year projections. These solutions can be scaled one year at a time, spreading the investment.

Therefore, the key to achieving the desired ROI with robotic implementation is ensuring that the robotic solution is scalable and flexible.

What industries should invest?

- e-Commerce

- e-Retail

- Food and beverage

- Healthcare

- Manufacturing

- Third-party logistics (3PL)

Any business that has a supply chain and order fulfillment process can benefit from robotics in some way. When considering warehouse automation, it’s important to look at the big picture and how robotics can help your company not just today but in the future as well.

Is it right for your supply chain?

When making these decisions for your supply chain and warehouse operations, a factor to consider is how these systems will affect your current culture and workforce environment since associates will need to interact with them daily. The key to successfully integrating these types of systems is to ensure proper training and keep open communication between associates and management.

There are so many parameters to consider, so it is wise to partner with an integrator for your project. An integrator specializes in sourcing the appropriate automated systems to maximize the throughput, productivity, efficiency, and ROI. An integrator, like AHS, ensures the individual technologies work cohesively together, so there is no guesswork.

FAQ

How much does it cost to automate a warehouse?

The cost to automate a warehouse can vary greatly depending on the size and complexity of the warehouse, as well as the type of automation equipment used. A fully automated warehouse can easily run over $30 million, while a semi-automated will typically fall between $5 and $15 million.

What are the benefits of warehouse automation?

• Increased warehouse throughput

• Using resources more efficiently

• Savings on labor and recruiting costs

• Improved customer service

• Reduced handling and storage costs

• Replacement of repetitive tasks

How many warehouses use automation?

As of 2020, it is estimated that around 20% of warehouses use some form of automation. This number is expected to grow in the coming years as more and more warehouses adopt new technologies to improve efficiency.