In today’s market, supply chains need to be agile, responsive, and scalable. Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) are two essential tools that facilitate this by automating processes and capturing valuable data. According to Peerless Research Group, the top three supply chain initiatives that businesses are focusing on with software applications are:

- Inventory Visibility

- Demand Planning

- Procurement

Source: Peerless Research Group

ERP and WMS play a significant role in achieving these goals, though many mistakenly use these terms interchangeably. It is important to understand their differences to make informed decisions and avoid unnecessary expenses down the road.

What is an ERP System?

An Enterprise Resource Planning (ERP) system is an integrated business management solution designed to collect, store, and interpret data related to various aspects of a business, including accounting, procurement, project management, compliance, and supply chain operations. While there is some overlap between ERP and WMS functionalities, ERPs are primarily geared toward managing financial data.

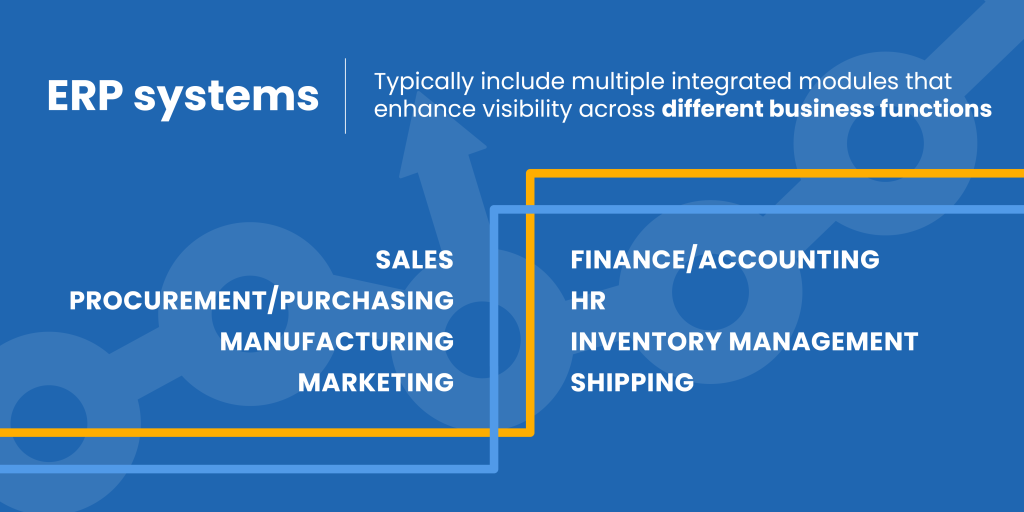

ERP systems typically include multiple integrated modules that enhance visibility across different business functions:

- Sales

- Procurement/Purchasing

- Manufacturing

- Marketing

- Finance/Accounting

- HR

- Inventory Management

- Shipping

While ERP solutions offer visibility into warehousing functions, they focus more on financial aspects, tracking the value of inventory and facilitating high-level decision-making.

What is a WMS?

A Warehouse Management System (WMS) is a specialized software solution that captures, stores, and analyzes data related to warehouse operations, providing insights into how goods move in and out of the warehouse.

For instance, a WMS can provide reports based on historical data that help determine the optimal pick location for every SKU. It captures data regarding:

- Sales

- Order Fulfillment

- Shipping

- Replenishment

- Inventory

- Racking

- Manufacturing Raw Materials

WMS solutions are crucial for real-time decision-making and help streamline warehouse operations, enhance productivity, and optimize storage through insights derived from data analysis.

ERP and WMS: Understanding the Differences

The main distinction between ERP and WMS software lies in their focus:

- ERP systems are primarily accounting-oriented and focus on automating overall business processes. They analyze business performance against financial metrics.

- WMS software focuses on managing warehouse-specific data and optimizing the movement and storage of inventory in real-time.

In other words, ERP systems help you understand the financial value of your inventory, while WMS solutions provide more granular, real-time information for improving warehouse efficiency.

ERP WMS Modules vs. True WMS Solutions

With the rise of ERP systems, many providers offer WMS modules as an extension to their core system. These modules integrate easily with ERP systems and seem like an all-in-one solution. However, a WMS module integrated into an ERP system is not as robust as a true WMS. As a business grows, the ERP’s WMS module may struggle to scale efficiently.

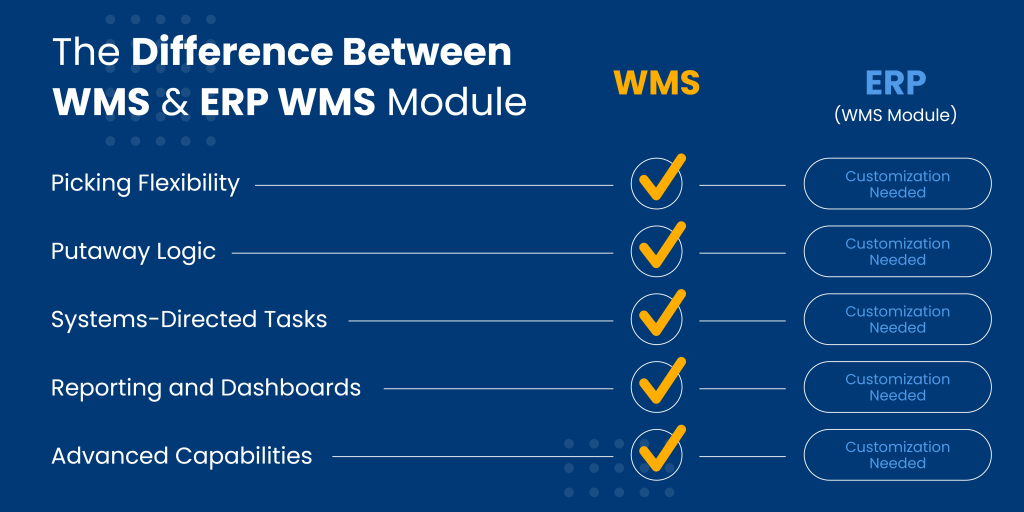

Here are key areas where a true WMS differs from an ERP WMS module:

Picking Flexibility: A true WMS offers advanced picking options, like voice-directed picking or pick-to-box, adapting to unique operational needs. ERP WMS modules often have limited picking methods.

Putaway Logic: Advanced putaway rules are possible with a true WMS, enabling efficient use of space across zones. In contrast, ERP WMS modules generally use a single putaway location, lacking sophisticated logic.

Systems-Directed Tasks: Many WMS solutions enable systems-directed tasks, allowing workers to switch between different types of tasks, reducing inefficiencies, and improving productivity. ERP modules typically have limited task management capabilities.

Reporting and Dashboards: Real-time data and operational dashboards are essential for managing a warehouse efficiently. A true WMS provides rich, customizable reports and dashboards, often accessible online. ERP WMS modules usually lack real-time data and comprehensive dashboards.

Advanced Capabilities: True WMS solutions offer advanced features like transportation management, labor management, dock scheduling, and seamless integration with robotics. ERP WMS modules usually do not provide these advanced capabilities.

While ERP WMS modules can be a suitable choice for smaller operations with a predictable flow, a true WMS provides the depth and flexibility needed to grow and optimize a more complex warehouse environment.

WMS or ERP for Omnichannel Fulfillment

With the rise of omnichannel fulfillment, businesses need software solutions that can manage the complexity of serving multiple channels while optimizing the flow of goods and data. Most companies choose to use both ERP and WMS to support their omnichannel operations:

- WMS provides granular, warehouse-specific data—helpful for order fulfillment.

- ERP integrates data across channels, allowing for visibility from inventory sourcing to final delivery.

Conclusion

Today’s complex supply chain operations demand a well-orchestrated approach to data management and process automation. ERP and WMS solutions overlap in some areas, but they serve distinct roles in optimizing supply chain performance. A true WMS enhances warehouse efficiency by providing detailed insights and facilitating advanced logistics processes, whereas an ERP system offers a comprehensive view of business operations, especially focusing on accounting and financial performance.

If your business needs seamless growth, operational flexibility, and optimized inventory management, a true WMS solution, like Hy-Tek’s IntraOneTM full stack software suite, is a better investment. The IntraOneTM software can help you keep track of orders, inventory, and labor with seamless control and coordination of people, products, and automation. Gain real-time visibility and make data-driven decisions that deliver measurable results—backed by 24/7 expert support you can trust

Ultimately, choosing between an ERP WMS module and a true WMS comes down to understanding your business’s current and future needs. Working with WMS and ERP experts can help ensure that you make the right choice for your business goals.

FAQ

What is the difference between ERP and WMS?

ERP systems primarily focus on automating overall business processes and financial analysis, while WMS solutions are specialized for inventory management and warehouse operations optimization.

Can a WMS integrate with an ERP?

Yes, ERP integration is a key feature of Hy-Tek’s IntraOneTM software, providing a holistic view of business and operational data.

What are the benefits of using a WMS over an ERP for warehouse management?

A true WMS offers advanced warehouse capabilities, including flexible picking methods, intelligent putaway logic, real-time dashboards, and task interleaving, allowing for greater efficiency and flexibility. In contrast, ERP systems focus on financial and high-level inventory accounting, lacking specialized warehousing features.

Can I use both ERP and WMS together?

Yes, many companies use both ERP and WMS in tandem. ERP systems help manage overall business functions and financial data, while WMS focuses specifically on optimizing warehouse operations. Integration between the two provides a holistic view of business performance from procurement to shipping.

Does a WMS support advanced automation technology?

Yes, many WMS solutions support integration with advanced automation technologies, such as robotics, Automated Storage and Retrieval Systems (AS/RS), and autonomous mobile robots (AMRs). This allows businesses to leverage automation to improve efficiency, reduce labor costs, and enhance scalability. Hy-Tek’s IntraOne software seamless integrates with our preferred automation technology partners, including but not limited to Exotec, Hai Robotics, Geek+, Tompkins Robotics, and many more.