If industrial vertical storage systems are on your radar, chances are your warehouse, manufacturing, or distribution facility has forced you to reevaluate your space and handling systems.

Vertical storage systems are one of the easiest methods for reclaiming unused square footage and elevating the handling processes of your product.

While every company situation and investment budget is unique, there are practical vertical storage systems that are affordable at varying price levels with two of the most used types being vertical lift tables and vertical storage carousels.

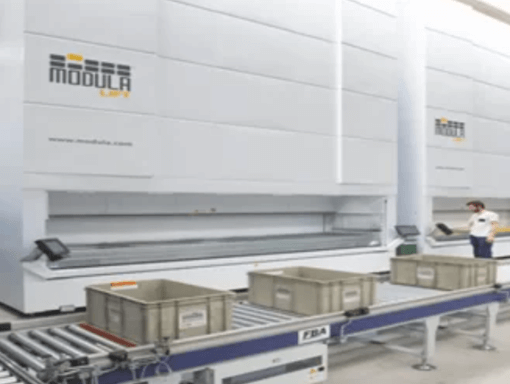

Vertical Lift Modules (VLM) are enclosed systems that contain two columns of trays with an inserter/extractor in the middle of the system.

With the push of a button the inserter/extractor retrieves trays from the front and back of the unit and delivers the goods to the operator at the base of the system.

Below is a video that provides a great overview as to how VLMs work.

Vertical Storage Carousels are enclosed systems that have a series of carriers attached in fixed locations to a chain drive.

The carriers move in a vertical loop around a track in forward and reverse directions and delivers the goods to the operator at a window at the base of the system.

Below are some quick tips on how to navigate the potentials of vertical storage systems.

If the focus is solely on space:

Creating vertical storage in a small foot print is generally the first and most budget friendly move over finding and investing in a larger space.

Static shelving is the solution option in this instance as it is lower cost, easy to source, ergonomic, and safe.

If the focus is on space and quick access:

When evaluating the potential for vertical storage systems in your facility, beyond static shelving, consider the benefits of entry level automation.

This is especially true in applications when the number of small piece inventory items are in the 300 to 400 range and the emphasis is on quick access to all pieces.

For example, if a luxury jewelry manufacturer has thousands of individual units and needs not only to optimize shelf space but also reduce theft, then a VLM or vertical storage carousel would make sense for their application.

If the focus is on space, quick access and asset protection:

When securing high-value inventory is at stake, vertical storage systems become an even more appealing investment.

By limiting employee access (badges/I.D’s) to certain high-value items, this type of system allows for an overall improvement in accuracy and accountability.

If the focus is on space, accuracy, safety, and efficiency:

In specialty environments where heavy or particularly awkward picking is the priority, industrial vertical storage systems are not only a clever but essential solution.

This is equally valid in other environments where extremely clean or hazardous picking are a significant concern.

Quick Facts on Industrial Vertical Storage Systems:

- In manufacturing, return on investment (ROI) averages 5 years, but 1 to 1 ½ years ROI in distribution.

- In space and reduction of overhead (i.e. 15 people to 3 people), ROI averages 2 to 2 ½ years.

- Vertical storage has been around for 20 years, but new advantages in the software capabilities (pick to light, laser pointers, etc.) is the reason to take another look.

The bottom line is that unless your company has really low inventory or unlimited space, vertical storage systems are a worthwhile investment for almost every environment.

More importantly, it can combine multiple storage and handling improvements in one seamless solution.

To learn more, contact your local material handling expert to conduct a vertical storage systems audit on your facility.

FAQ

How to Calculate Storage Capacity of Warehouse?

Subtract your non-storage square footage (offices, loading area, etc.) from your warehouse sq. footage and then multiply by your clear height.

Warehouse Square Footage – Non-Storage Square Footage) X Clear Height = Storage Capacity of Warehouse

What is a Vertical Storage System?

A vertical storage system is an automated storage & retrieval solution that builds vertical layers of boxed goods and brings the goods to you, rather than picking an order yourself.