Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years. It is important to outline the process and timeline to ensure that your implementation goals are met.

According to the 2022 MHI Annual Industry Report, 87% of companies say that the pandemic has altered strategic importance of supply chain operations and 64% are increasing supply chain investments.

Below are 3 tips to help your company develop an accurate timeline, so that you can start planning far enough in advance.

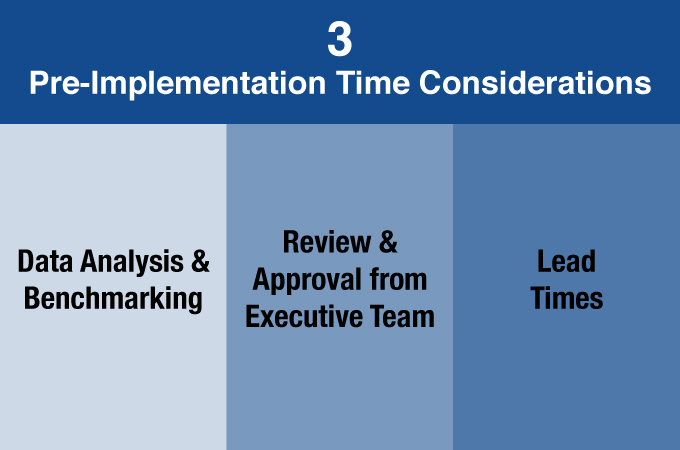

1. Set realistic expectations for a pre-implementation timeline

What is a realistic timeline?

The timeline is dependent on the complexity of the business, in addition to the technology, system, or software being considered. There are several upfront processes and considerations that impact the overall timeframe:

- Data analysis to find the appropriate solution

- Approval from your Executive Team or others involved

- Lead times for specific parts and systems

These timeframes are not necessarily sequential and may overlap with each other.

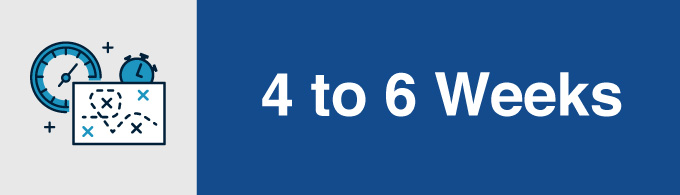

Data Analysis

We use the data analysis process to give us a clearer understanding of the level of automation needed, constraints in the business, planning requirements, etc.

The data analysis process is a discovery phase where we are trying to understand the profile of an operation, so we can recommend appropriate hardware and software solutions.

For example, if it is a wholesaler that services multiple channels, then we spend more time understanding the different behaviors of the channels. Or if it is a business that operates with heavy SKU relationships, then we will dig deeper into SKU affinity.

Solutions can vary dramatically based on what the data tells us. We may spend a significant amount of time digging very deep into the different service channels to come to the conclusion that the best fit for an operation may be less automated hardware and more focused around correct software solutions. For example, we have to consider regional distribution center replenishment orders, will-call orders, installation job orders, etc. because they behave so differently, and one solution may not satisfy each channel. In addition, their orders are placed by installers in “job form”, which is everything you need to install a system. As a result, you get strong relationships in SKUs within an order.

On average, our Data Analytics team will spend 4-6 weeks engaged on a project, but the level of effort varies within that time-period – heavy on the front end with organizing and analyzing data, and then it shifts into more of follow-up analysis and deep discussions with our customers.

The goal of our Data Analytics team is to add value to the customer in the front-end process. In addition to supporting us internally in generating design requirements, the team leverages creative ways to look at the data that makes the customer say “Huh, we never looked at it like that, and that tells a very different story”.

Approval Process

Once we perform the data analysis and can make a recommendation on which system or software to pursue, the ball is really in the customer’s court for the approval process timeframe. Each company is different with the number of approvals the project requires, and this can be a week-long process or a two-month long process. However, we aid in the discussion whenever possible and help you back up the case for proposed project through our data analysis findings.

System Lead Times

Once the data analysis and approval process are complete, we begin ordering the components and systems required to complete the project. Over the past year, the supply chain has been volatile across industries and continues to change very quickly. However, in general, the timelines below detail how long it may take for different components and systems to be shipped and delivered on site.

Engineering Design: (job specific) ~4-6 weeks

Sortation equipment (dependent of sorter & manufacture): ~18-24 weeks

Exotec: 18 weeks +/- 2 weeks

Conveyor: ~16 weeks

Pick Module (frame dependent): ~15 weeks

Selective Rack: ~7 weeks

2. Work with a collaborative and supportive supply chain consultant & integrator

A supply chain consultant and systems integrator will have a broader view of the industry and will have insights to questions like:

- Are my distribution and fulfillment facilities in the optimal location?

- Can I retrofit my existing fulfillment center to address business growth?

- What systems make sense to implement to reach the overall goal?

A systems integrator has the capabilities and expertise to facilitate communication between the warehouse systems that do not normally communicate. We ensure that all the systems are working harmoniously to increase productivity and data consistency.

The benefit of working with a systems integrator is they know how each system operates and communicates together versus a system manufacturer that will only know how its own system operates. It can also promote consistency, flexibility, and most importantly innovation.

- Consistency. Automated exchange of information between systems is more reliable and efficient when there is a proper system integration.

- Scalability & Flexibility. A systems integrator will understand your goals for next year and 10 years from now, and they will implement solutions that can support that growth at a pace that the constraints (capital, space, time) allow.

- Innovation. Top players in the warehousing and fulfillment industry are vying to be the most innovative. Warehouse and fulfillment automation is essential to meeting customer demands in e-commerce, while keeping costs and operational complexity under control. Online retailing is primarily a logistics business that focuses on margin improvement through cost reduction in inventory management, order fulfillment, and delivery capabilities. A systems integrator is necessary to ensure that all aspects of the business are considered.

Plan for Go-Live Testing, Operational Readiness, & Support

The Operational Readiness phase consists of a wide range of activities that are required to get the facility from an idle facility to a fully operational facility. These activities are oriented to prepare the operations team as well as minimize Go-Live live risk through sufficient preparation and planning.

Operational Readiness Activities

These tasks will take 4-8 weeks on average where small, simple projects can take as little as 2 weeks and complex projects can take between 3-4 months.

Below is a list of activities we complete during the operational readiness stage which sometimes includes additional tasks depending on the project.

- Inventory Migration Planning & Execution

- Item Slotting Planning & Execution

- Staff Planning

- SOPs

- 7S and Signage Planning

- Item Dimensioning Program Oversight

- WMS Location Labeling Definition and Oversight

- WMS Readiness

- Operational Preparation Oversight (supplies ordering, recycling contracts, etc.)

- Facilities Preparations

- Training

- Ramp-Up Planning & Scheduling

Testing Timeline:

Once a system’s MHE and hardware have been installed and software integrated, the testing phase begins. The goal of testing is two-fold. First, since testing the entire system allows us to simulate the targeted environment, we have the ability to further calibrate MHE, align system timing, and work out system kinks and potential bottlenecks. Second, testing allows validation of the designed solution. It’s essential to verify the result meets and/or exceeds design rates and throughput.

Similar to other phases of a project, the testing time period can vary vastly based upon what hardware and software have been put in place, the complexity of integration with external systems (WMS or ERP for example), and any specific validation or certification requirements based on the product stored in the system. A small system may take as little as two weeks to test and validate the system whereas a more complex system requiring certification may date 40-60 days.

Summary

Today’s supply chain constraints can seem daunting to overcome when first beginning your warehouse automation planning however by being proactive in taking time to understand your needs and what solutions fit them best you can mitigate these disruptions by planning for accurate lead times. Having that information upfront to properly educate your stakeholders on how long the entire project will take, will set your warehouse automation project up for success and put you ahead of the competition that doesn’t seek out the latest lead times.